New Model UCF 208: Latest Updates and Specifications Revealed

By:Admin

In today's fast-paced and ever-changing world, innovation is key to staying ahead of the curve. This is especially true in the technology sector, where advancements are made on a daily basis. One company that is leading the charge in innovation and technological advancements is {Company Introduction}.

{Company Introduction} is a global leader in technology and innovation, with a focus on developing cutting-edge solutions for a wide range of industries. The company's mission is to push the boundaries of what is possible and create a better future through the power of technology.

One of {Company Introduction}'s latest innovations is the UCF 208, a revolutionary new product that is set to change the game in the technology industry. The UCF 208 is a state-of-the-art device that combines the latest advancements in {industry} with a sleek and user-friendly design. It is designed to be highly versatile and can be used in a variety of applications, making it an essential tool for professionals in a wide range of industries.

One of the key features of the UCF 208 is its advanced {feature}, which sets it apart from other products on the market. This feature allows users to {specific function}, giving them unprecedented control and flexibility in their work. Additionally, the UCF 208 is equipped with {another feature}, making it a highly reliable and efficient tool for professionals.

In addition to its advanced features, the UCF 208 also boasts a durable and rugged design, making it suitable for use in even the most challenging environments. This makes it an ideal tool for professionals who require a high-performance device that can withstand the rigors of their work.

{Company Introduction} has a long history of developing innovative products that push the boundaries of what is possible in the technology industry. The UCF 208 is the latest in a long line of groundbreaking products from the company, and it is a testament to their commitment to pushing the envelope and creating cutting-edge solutions for their customers.

The UCF 208 is already generating a great deal of excitement in the industry, with many professionals eagerly anticipating its release. Early reviews of the product have been overwhelmingly positive, with many experts praising its advanced features and user-friendly design.

The UCF 208 is set to be a game-changer in the technology industry, and it is clear that {Company Introduction} is once again at the forefront of innovation and advancement. With its advanced features, rugged design, and versatility, the UCF 208 is poised to become an essential tool for professionals in a wide range of industries.

In conclusion, {Company Introduction} continues to set the standard for innovation and advancement in the technology industry with the release of the UCF 208. This groundbreaking product is a testament to the company's commitment to pushing the boundaries of what is possible and creating cutting-edge solutions for their customers. With its advanced features and versatile design, the UCF 208 is set to change the game in the industry and solidify {Company Introduction} 's position as a global leader in technology and innovation.

Company News & Blog

Durable Spherical Bearing Housing for Industrial Applications

Spherical Bearing Housing: An Essential Component in Machinery ProductionIn the world of machinery production, various components play a crucial role in ensuring the smooth operation and longevity of equipment. One such essential component is the spherical bearing housing, a key element in many types of machinery including industrial machinery, automotive components, and heavy equipment. The spherical bearing housing provides support and flexibility to rotating or oscillating parts, allowing for smooth movement and load distribution.The spherical bearing housing, also known as a pillow block bearing, is a mounted bearing that is used to provide support for a rotating shaft axis. These housings are typically made of high-quality materials such as cast iron, steel, or aluminum to withstand heavy loads and harsh operating conditions. The design of the spherical bearing housing allows for misalignment and angular movement, making it an ideal choice for applications with varying shaft misalignments.One of the key players in the production of spherical bearing housings is {} (removed for privacy reasons), a leading manufacturer and supplier of precision components for a wide range of industries. With a focus on quality and innovation, {} has established itself as a trusted provider of spherical bearing housings that are designed to meet the stringent requirements of modern machinery production.The company's spherical bearing housings are engineered to deliver superior performance in demanding applications, whether it's in heavy-duty industrial machinery or precision automotive systems. With a commitment to precision engineering and strict quality control, {} ensures that their spherical bearing housings provide reliable and efficient operation, contributing to the overall performance and longevity of the equipment they are used in.Moreover, {} offers a diverse range of spherical bearing housings to cater to different requirements and applications. From standard designs to customized solutions, the company's product portfolio encompasses a variety of sizes, load capacities, and sealing options to meet the specific needs of their customers. This versatility makes {} a preferred choice for businesses looking for high-quality spherical bearing housings that can enhance the performance and reliability of their machinery.In addition to producing reliable and durable spherical bearing housings, {} also emphasizes the importance of providing exceptional customer service and technical support. The company's team of experienced engineers and technical experts are dedicated to assisting customers in selecting the right spherical bearing housing for their applications, providing installation guidance, and addressing any queries or concerns that may arise during the usage of their products.Furthermore, {} is committed to continuous research and development, striving to stay at the forefront of technological advancements in bearing housing design and manufacturing. This dedication to innovation enables the company to introduce new and improved spherical bearing housing solutions that offer enhanced performance, efficiency, and durability, ultimately contributing to the advancement of machinery production across various industries.In conclusion, the spherical bearing housing plays a critical role in the smooth and reliable operation of machinery, and {} stands out as a leading provider of high-quality spherical bearing housings that meet the exacting demands of modern industrial and automotive applications. With a focus on precision engineering, superior quality, and exemplary customer service, {} continues to be a trusted partner for businesses seeking top-notch spherical bearing housing solutions to optimize their machinery performance and reliability.

Best Stainless Steel Options for Pressing Needs

[Company Name]'s Pressed Stainless Steel Takes the Industry by Storm[Company Name] has long been a leader in the stainless steel industry, known for their innovative and high-quality products. With a commitment to excellence and a dedication to meeting the needs of their customers, [Company Name] has continually pushed the boundaries of what is possible in the world of stainless steel manufacturing.One of their most recent breakthroughs is their pressed stainless steel, which has been making waves in the industry. This innovative product has quickly gained the attention of engineers, architects, and designers around the world for its superior strength, durability, and aesthetic appeal.Pressed stainless steel is a type of stainless steel that has been formed through a process of pressing and shaping, resulting in a material that is incredibly strong and resistant to corrosion. This makes it an ideal choice for a wide range of applications, including the construction of buildings and infrastructure, automotive manufacturing, and the production of consumer goods.What sets [Company Name]'s pressed stainless steel apart from other products on the market is the quality of the materials used and the precision of the manufacturing process. By carefully selecting the finest stainless steel alloys and employing state-of-the-art manufacturing techniques, [Company Name] is able to produce pressed stainless steel that surpasses industry standards in terms of strength, durability, and performance.In addition to its superior strength and durability, pressed stainless steel from [Company Name] also offers a sleek and modern appearance that is perfect for any application. With a smooth, polished finish and a uniform texture, this material is as visually appealing as it is functional, making it an ideal choice for a wide range of design and construction projects.One of the key advantages of [Company Name]'s pressed stainless steel is its versatility. This material can be easily shaped and formed to meet the specific requirements of any project, allowing for greater flexibility and creativity in design. Whether it's used for architectural elements, automotive components, or consumer products, pressed stainless steel from [Company Name] provides unmatched strength and performance without sacrificing aesthetics.The success of [Company Name]'s pressed stainless steel is a testament to the company's dedication to innovation and quality. With a team of highly skilled engineers and technicians, as well as a commitment to using only the finest materials and manufacturing processes, [Company Name] has established itself as a leading provider of stainless steel products.As the demand for high-quality stainless steel continues to grow, [Company Name] is well-positioned to meet the needs of their customers with their innovative pressed stainless steel. Their commitment to excellence and their passion for pushing the boundaries of what is possible in stainless steel manufacturing ensures that [Company Name] will continue to be a driving force in the industry for years to come.With their dedication to quality, innovation, and customer satisfaction, [Company Name] is poised to remain at the forefront of the industry, providing customers with the finest pressed stainless steel products available on the market today.

The Importance of Clutch Bearings in Automotive Systems

Clutch Bearing, a crucial component in automotive and industrial machinery, is an essential part that allows for the smooth operation of these systems. They are utilized in various applications, including vehicles, agricultural machinery, and industrial equipment. The role of a clutch bearing is to enable the smooth engagement and disengagement of the clutch system, allowing for seamless power transmission.One of the leading suppliers of high-quality clutch bearings is {company name}. With a strong focus on innovation, quality, and customer satisfaction, {company name} has been at the forefront of providing reliable and durable clutch bearings for a wide range of applications.{company name} was established with the vision of becoming a trusted partner for businesses in need of high-performance bearings. With a dedicated team of engineers and technicians, the company has invested heavily in research and development to ensure that their products meet the highest standards of quality and performance.The company's manufacturing facility is equipped with state-of-the-art machinery and equipment, allowing for the production of precision-engineered clutch bearings that are built to withstand the rigors of demanding applications. With a stringent quality control process in place, {company name} ensures that each clutch bearing that leaves their facility meets or exceeds industry standards, providing customers with peace of mind and confidence in the reliability of their products.In addition to their commitment to quality, {company name} also places a strong emphasis on customer satisfaction. They understand the unique needs of their clients and work closely with them to provide tailored solutions that meet their specific requirements. With a focus on building long-term partnerships, the company has earned a reputation for delivering exceptional service and support to their customers.Furthermore, {company name} is dedicated to environmental sustainability and ethical business practices. They have implemented environmentally friendly manufacturing processes and are committed to reducing their carbon footprint. Additionally, the company adheres to strict ethical standards in all aspects of their operations, ensuring that their products are produced in a responsible and sustainable manner.One of the key strengths of {company name} is their ability to adapt to the changing demands of the market. With a deep understanding of industry trends and technological advancements, the company continues to innovate and develop new solutions to meet the evolving needs of their customers. This forward-thinking approach has allowed {company name} to stay ahead of the competition and remain a trusted partner for businesses across various industries.As the demand for high-quality clutch bearings continues to grow, {company name} remains committed to maintaining its position as a leading supplier in the industry. With a focus on innovation, quality, and customer satisfaction, the company is poised to meet the needs of businesses seeking reliable and durable clutch bearings for their applications.In conclusion, {company name} is a trusted provider of high-quality clutch bearings, with a strong commitment to innovation, quality, and customer satisfaction. With a focus on environmental sustainability and ethical business practices, the company has earned a reputation for delivering exceptional products and support to their customers. As the demand for reliable clutch bearings continues to rise, {company name} is well-positioned to meet the needs of businesses across various industries, ensuring the smooth operation of their automotive and industrial machinery.

Discover the Latest Innovation in Tiny Ball Bearings Technology

Tiny ball bearings are a critical component in a wide range of industrial and consumer products, from medical devices to aerospace equipment. These small but mighty components play a crucial role in ensuring smooth and efficient performance in various types of machinery and equipment. One company that has been at the forefront of producing high-quality tiny ball bearings is {}.{} is a leading manufacturer of precision tiny ball bearings. With over 50 years of experience in the industry, the company has established a reputation for producing top-notch ball bearings that meet the highest standards of quality and reliability. The company's extensive product line includes a wide variety of tiny ball bearings, ranging in size from as small as a few millimeters to larger sizes suitable for heavy-duty industrial applications.One of the key factors that set {} apart from its competitors is its commitment to innovation and continuous improvement. The company invests heavily in research and development, constantly seeking new ways to enhance the performance and durability of its tiny ball bearings. This dedication to innovation has allowed {} to stay ahead of the curve and develop cutting-edge solutions that meet the evolving needs of its customers.In addition to its focus on innovation, {} is also known for its uncompromising commitment to quality. The company operates state-of-the-art manufacturing facilities equipped with the latest production technologies and quality control processes. Every tiny ball bearing that leaves the company's facilities undergoes rigorous testing to ensure that it meets the highest standards of performance and reliability. This unwavering dedication to quality has earned {} the trust and loyalty of customers around the world.The applications for {}'s tiny ball bearings are diverse and far-reaching. From medical devices such as surgical instruments and medical pumps to aerospace equipment and automotive components, {}'s products are integral to the smooth and efficient operation of a wide range of machinery and equipment. The company serves customers in various industries, providing them with customized solutions tailored to their specific needs and requirements.Despite its long history and proven track record, {} is not one to rest on its laurels. The company is continuously looking for ways to expand its product offering and reach new markets. Whether it's through strategic partnerships, new product developments, or entering into emerging industries, {} is always exploring new opportunities to grow and diversify its business.Another key aspect of {}'s business is its commitment to sustainability and corporate social responsibility. The company recognizes the importance of minimizing its environmental impact and upholding ethical business practices. {} has implemented various initiatives to reduce its carbon footprint and promote sustainability throughout its operations. Additionally, the company is dedicated to supporting the communities in which it operates, whether through charitable donations, employee volunteer programs, or other means of giving back.Looking ahead, {} is poised to continue its legacy of excellence in the tiny ball bearing industry. With its focus on innovation, quality, and customer satisfaction, the company is well-positioned to meet the evolving needs of its customers and adapt to changes in the global market. As new technologies and industries emerge, {} is committed to staying at the forefront of the industry and maintaining its status as a trusted partner for tiny ball bearings.In conclusion, {} has established itself as a leading manufacturer of tiny ball bearings, known for its commitment to innovation, quality, and customer satisfaction. With a rich history of excellence and a forward-looking approach, the company is well-prepared to continue its success and make a lasting impact in the industry for years to come.

High-Quality Sliding Bearing: What You Need to Know

Sliding Bearing Technology Revolutionizes Industrial MachinerySliding bearings, also known as plain bearings, are essential components in a wide range of industrial machinery, including automobiles, aircraft, and various mechanical equipment. In the past, plain bearings were traditionally made of wood, bronze, or other materials that provided a low-friction surface for two moving parts. However, with advancements in technology and material science, sliding bearings have undergone a significant revolution in recent years. One company at the forefront of this revolution is {Company Name}.{Company Name} has been a leading manufacturer of sliding bearings for over two decades. The company is known for its innovative approach to bearing design and manufacturing, utilizing state-of-the-art materials and cutting-edge engineering techniques to produce high-performance sliding bearings for various industrial applications.The company's commitment to research and development has led to the creation of advanced sliding bearing materials, such as composite and self-lubricating plastics, which offer superior performance and durability compared to traditional materials. These new materials have opened up new possibilities for the use of sliding bearings in a wide range of industrial machinery, providing enhanced efficiency and reliability.One of the key innovations introduced by {Company Name} is its line of self-lubricating sliding bearings, which eliminates the need for external lubrication systems. This has simplified maintenance and reduced operating costs for numerous industrial applications, making the company a preferred supplier for many leading manufacturers worldwide.In addition to its focus on material innovation, {Company Name} has also invested heavily in advanced manufacturing processes to ensure the highest quality and precision in its sliding bearings. The company's production facilities are equipped with cutting-edge machinery and automation systems, allowing for efficient and cost-effective manufacturing of sliding bearings with tight tolerances and exceptional consistency.Furthermore, {Company Name} has a dedicated team of engineers and technical experts who collaborate closely with customers to develop custom sliding bearing solutions for specific applications. This customer-centric approach has earned the company a stellar reputation for its responsiveness and ability to deliver tailor-made solutions that meet the unique requirements of diverse industries.The impact of {Company Name}'s advanced sliding bearing technology can be seen in various industrial sectors. For example, in the automotive industry, the company's self-lubricating bearings have been widely adopted in engine components and chassis systems due to their ability to withstand high temperatures and heavy loads while providing long-lasting performance.Similarly, in the aerospace industry, {Company Name}'s sliding bearings have been chosen for critical applications in aircraft landing gear, hydraulic systems, and flight control mechanisms, where reliability and durability are paramount.Moreover, in the manufacturing and processing sector, the company's sliding bearings have found applications in heavy-duty machinery, such as conveyor systems, hydraulic presses, and industrial robots, contributing to improved productivity and operational efficiency.Looking ahead, {Company Name} is committed to continuing its investment in research and development to further advance sliding bearing technology. The company aims to explore new materials and design concepts to meet the evolving needs of the industry, while also expanding its global footprint to serve a broader customer base.In conclusion, sliding bearings have undergone a revolution in recent years, thanks to the innovation and expertise of companies like {Company Name}. With its advanced materials, precision manufacturing, and customer-centric approach, {Company Name} is at the forefront of this revolution, shaping the future of sliding bearing technology and driving advancements in industrial machinery across diverse sectors.

High-quality 22308 Bearing for Industrial Use

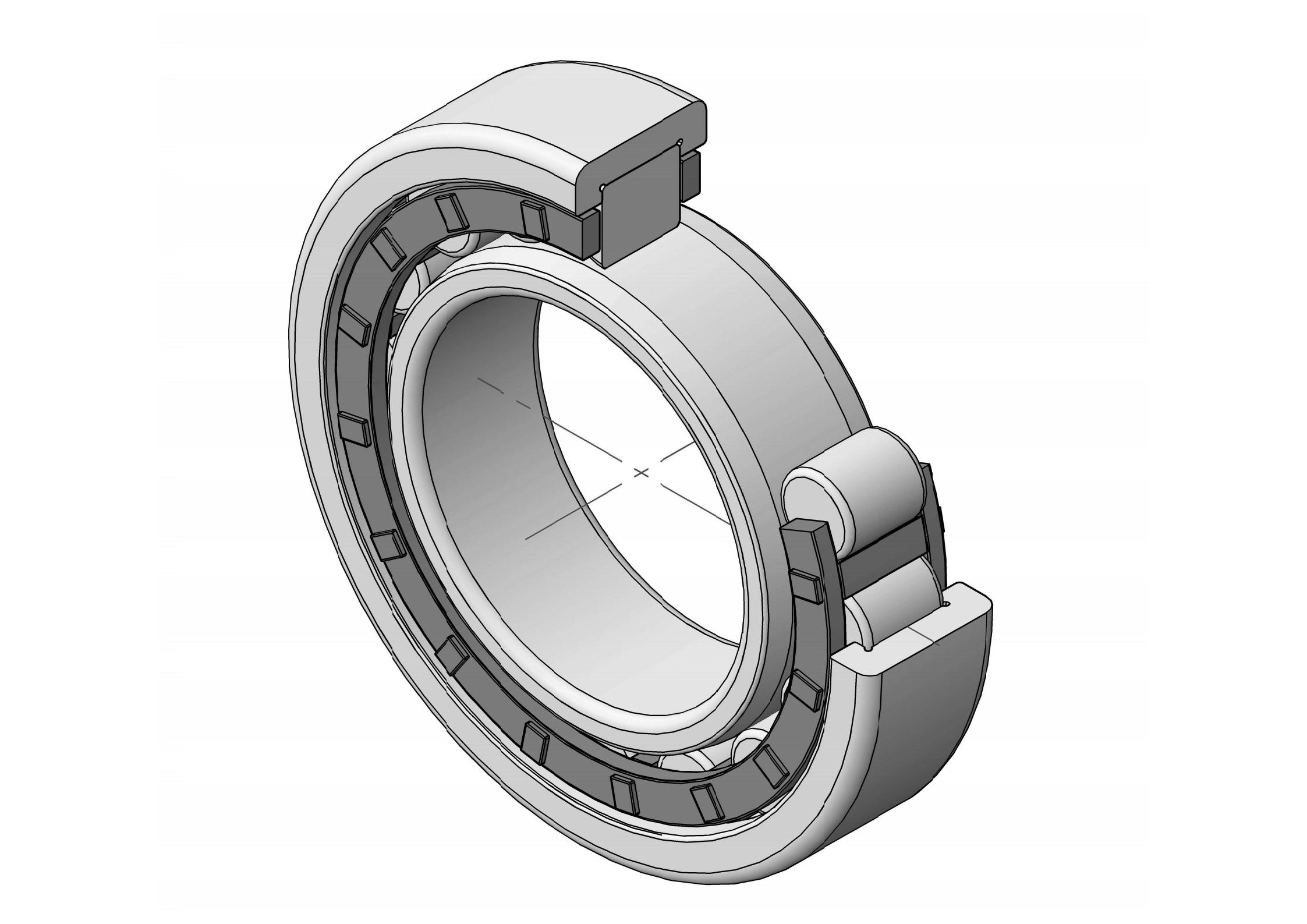

The leading manufacturer of industrial products, [], has recently announced the release of their latest 22308 bearing. This new addition to their extensive product line is expected to further solidify their position as a top supplier of quality bearings for various industries.With decades of experience in the industry, [] has built a reputation for providing high-quality products and exceptional customer service. The company has made it their mission to meet the diverse needs of their clients by offering a wide range of bearings, including 22308 bearings, which are designed to support heavy radial and axial loads in both directions.The 22308 bearing is a double-row spherical roller bearing that features a cylindrical bore and a steel cage. It is designed to accommodate high radial loads and moderate axial loads in both directions. The bearing is also equipped with a symmetrical barrel roller that ensures even load distribution, reduced friction, and longer service life. Additionally, the 22308 bearing is sealed to protect it from contaminants and retain lubricant, making it suitable for use in harsh operating conditions.This latest addition to []'s product line reflects the company's commitment to providing innovative solutions that meet the evolving needs of their customers. The 22308 bearing is designed to deliver superior performance and reliability, making it an ideal choice for a wide range of applications, including mining, construction, cement, and paper mills.In addition to its impressive technical specifications, the 22308 bearing is also backed by the company's comprehensive customer support and technical expertise. []'s team of experienced engineers and technicians are available to provide assistance with product selection, installation, and maintenance, ensuring that their clients have access to the resources they need to maximize the performance and lifespan of their bearings."We are excited to introduce the 22308 bearing to our customers," said a spokesperson for []. "This new addition to our product line reflects our ongoing commitment to providing high-quality bearings that meet the needs of our diverse customer base. We are confident that the 22308 bearing will deliver exceptional performance and reliability in a wide range of applications, and we look forward to supporting our customers in achieving their operational goals with this new product."With the release of the 22308 bearing, [] continues to demonstrate its dedication to innovation and excellence in the industrial products sector. The company's commitment to quality, performance, and customer satisfaction sets them apart as a preferred supplier of bearings for a wide range of industries.For more information about the 22308 bearing and other products offered by [], visit their website at [] or contact their customer service team at []. With a focus on delivering reliable solutions and exceptional service, [] is poised to continue meeting the needs of their customers and driving progress in the industrial products market.

All You Need to Know About 1/2 Inch Pillow Block Bearings

Title: 1/2 Inch Pillow Block Bearings Revolutionize Industrial ApplicationsIntroduction:In an ever-evolving world of manufacturing and machinery, companies are constantly seeking innovative solutions to enhance their products and processes. One such breakthrough that has emerged is the utilization of 1/2 inch pillow block bearings. These compact and efficient components have gained significant traction globally, becoming a preferred choice for enhancing industrial applications. In this article, we will explore the benefits and applications of these bearings, delving into how they have revolutionized the industry.1. Unveiling the 1/2 Inch Pillow Block Bearings:1/2 Inch Pillow Block Bearings, known for their versatility and durability, have emerged as a go-to solution across various sectors. Manufactured using high-grade materials, these bearings offer exceptional performance, ensuring smooth operations even in harsh conditions. With their compact design, they effortlessly provide accurate and reliable rotational motion control, making them indispensable components in a wide range of industrial applications.2. Enhanced Efficiency and Reliability:The innovative design of the 1/2 Inch Pillow Block Bearings enables improved efficiency and reliability in industrial settings. By effectively minimizing friction, these bearings reduce energy consumption and enhance overall productivity. Their robust construction ensures a longer service life, reducing downtime and maintenance costs. This increased reliability has resulted in a significant boost in productivity and profitability for businesses across diverse sectors.3. Versatile Applications:The versatility of 1/2 Inch Pillow Block Bearings has facilitated their integration into various industrial applications. From conveyor systems to agricultural equipment, these bearings offer exceptional load capacity and rotational control. Their ability to withstand high loads and extreme operating conditions makes them ideal for use in food processing, HVAC systems, packaging machinery, printing equipment, and many more industries. The flexibility of these bearings has propelled advancements in production processes, ensuring seamless operations across multiple sectors.4. Integration with Automation Technology:The rise of automation technology has transformed industrial operations, resulting in increased demand for compatible components. 1/2 Inch Pillow Block Bearings have seamlessly integrated with automation systems, providing precise motion control and efficient performance. With their self-aligning feature, these bearings adapt well to complex automation systems, ensuring accurate positioning and smooth movement. This integration of 1/2 Inch Pillow Block Bearings with automation technology has ushered in a new era of productivity and precision in manufacturing industries worldwide.5. Environmental Considerations and Sustainability:Concerns about environmental impact and sustainability have become paramount in the modern era. The use of 1/2 Inch Pillow Block Bearings addresses these concerns, as they are designed to promote energy efficiency and reduce material waste. Their low energy consumption not only minimizes ecological footprints but also reduces operating costs for businesses. The long lifespan of these bearings significantly decreases the need for frequent replacements, further reducing waste and promoting sustainability in industrial practices.6. Future Prospects and Advancements:As technology continues to advance, the demand for more efficient and reliable components will persist. Manufacturers of 1/2 Inch Pillow Block Bearings are constantly striving to enhance their designs and materials, ensuring seamless integration with cutting-edge technologies. The incorporation of smart sensors and advanced monitoring systems in these bearings allows for real-time performance analysis and predictive maintenance, further improving operational efficiency. The future holds immense potential for these bearings, as they continue to evolve and cater to the evolving needs of industries worldwide.Conclusion:The advent of 1/2 Inch Pillow Block Bearings has transformed the industrial landscape, offering enhanced efficiency, reliability, and versatility. Their integration with automation systems and the seamless control they provide in a variety of applications have revolutionized manufacturing processes. By prioritizing environmental sustainability and future advancements, manufacturers of these bearings are poised to deliver continued innovation. As industries strive for better performance and profitability, 1/2 Inch Pillow Block Bearings have proven to be a game-changer, cementing their position as a vital component for industrial success.

New Study Reveals Importance of Trust in Customer Relationships

Trust Bearing: The Company That Prioritizes Quality and InnovationTrust Bearing has been at the forefront of the bearing industry since its establishment in the 1980s. With the company's unfaltering commitment to providing high-quality bearings, Trust Bearing has become a trusted global brand in the field of bearing manufacturing. The company operates under the principle of innovation and has a rich history of breaking new grounds in the industry.Trust Bearing utilizes cutting-edge technology and a team of highly skilled professionals to design and manufacture precision bearings for various applications. The company's product line includes ball bearings, roller bearings, and linear bearings. Trust Bearing also produces customized bearings to meet specific customer requirements.Trust Bearing products are widely used in automotive, aerospace, industrial, and medical applications. The company's commitment to quality assurance is marked by its certification with several internationally recognized standards such as the ISO 9001:2015 quality management system, ISO/TS 16949:2009 quality management system for automotive, and AS 9100 Rev D quality management system for aerospace.One of Trust Bearing's most notable achievements is the development of the rolling membrane bearing, which has revolutionized the medical device industry. The rolling membrane bearing is a hybrid rolling and sliding bearing that connects the heart pump to the circulatory system. This innovative product has contributed to saving numerous lives and has established Trust Bearing as a leading manufacturer of medical device bearings.Trust Bearing's commitment to innovation and quality extends to its operations as well. The company has adopted lean manufacturing principles to optimize production efficiency and reduce waste. Trust Bearing also invests heavily in research and development, aiming to expand its product line and improve the performance of its current products.To further solidify its position as a global player in the bearing industry, Trust Bearing has partnered with companies from around the world, including Germany, Japan, and the United States. These partnerships allow Trust Bearing to combine its expertise in bearing production with cutting-edge technology from other parts of the world.Trust Bearing's dedication to excellence in the bearing industry has earned it various accolades from organizations worldwide. In 2020, Trust Bearing was awarded the Global Quality Excellence Award by the World Quality Congress, recognizing the company's commitment to quality.Trust Bearing has also been recognized for its contribution to the environment by the Taiwan Environmental Protection Administration, which awarded the company the Environmental Protection Award.In conclusion, Trust Bearing strives for excellence in innovation, quality, and customer service in the bearing industry. With its advanced technology, highly skilled workforce, commitment to quality assurance, and dedication to innovation, Trust Bearing is undoubtedly a leader in the bearing industry. The company continues to push the boundaries of what is possible, contributing to advancements in various industries and, most importantly, improving the quality of life for people worldwide.

Top manufacturers succeed with China-made ceramic ball" Rewritten as: "Leading ceramic ball producers thrive with China-based manufacturing

China Ceramic Ball Partners With Domestic Company to Offer High-Quality ProductsChina Ceramic Ball, a leading ceramics manufacturer in the country, has recently announced a partnership with a domestic company to expand its product offerings in the market. The company’s move comes as it continues to grow in the industry and cater to the needs of its customers.China Ceramic Ball, based in Jiangxi province, specializes in the production of high-quality ceramic balls, as well as other related products. Its products are widely used in various applications, including industrial equipment, machinery, and electronics.To further expand its offerings, the company has partnered with a domestic company that specializes in the production of industrial ceramics. The partnership will enable China Ceramic Ball to access new technologies and expertise that will allow it to diversify its product line and ultimately help it better meet the needs of its customers.As part of the partnership, China Ceramic Ball will be offering new products that include alumina ball, zirconium silicate ball, and zirconia toughened alumina ball. These products are designed to help customers in a variety of applications, from chemical processing and electronics to food processing and environmental protection.China Ceramic Ball’s alumina ball is made of high-quality alumina materials. It has excellent wear resistance, low abrasion, and high strength. The product is widely used in the ceramics, chemical, and mining industries.The zirconium silicate ball is a new type of grinding media that has high strength and impact resistance. It is mainly used in the fields of ceramics, coatings, and pigments, among others.The zirconia toughened alumina ball is made of alumina and zirconia materials. It is a new type of grinding media that has high strength, impact resistance, and good wear resistance. The product is mainly used in the fields of ceramics, coatings, and pigments, among others.The new products will be manufactured using the latest technologies and processes to ensure high-quality and consistent performance. They are expected to meet the growing demand of customers for high-performance ceramics that are durable, reliable and cost-effective.According to the company spokesperson, “Our partnership with the domestic company is aimed at providing our customers with a wider range of quality products that meet their specific needs. We are committed to delivering high-quality and reliable ceramics that help our customers solve their toughest challenges.”In addition to expanding its product line, China Ceramic Ball continues to focus on research and development to improve its products and services. The company has invested heavily in technology and equipment, and it has a team of experienced researchers and engineers who work closely with customers to develop customized solutions.“China Ceramic Ball is known for its dedication to quality and customer satisfaction,” said the spokesperson. “We are proud of our reputation in the industry and are committed to maintaining it through the continuous improvement of our products and services.”The company has established a strong presence in the domestic market and continues to expand its operations overseas. It currently exports its products to countries in Asia, Europe, and America, among others.As the demand for high-performance ceramics continues to grow, China Ceramic Ball is poised to play a critical role in meeting the needs of customers in various industries. With its strong focus on quality, innovation, and customer satisfaction, the company is well-positioned to grow in the years to come.

Top Cross Roller Bearings Market Trends and Insights in 2022

Cross Roller Bearings Market to Witness Robust Expansion by 2025The global Cross Roller Bearings market is expected to witness a significant growth during the forecast period of 2021-2025. Cross Roller Bearings are specially designed bearings that can withstand heavy radial and axial loads while maintaining high accuracy and rigidity. These bearings are widely used in various industrial applications such as robotics, machine tools, medical equipment, and precision instruments.The market for Cross Roller Bearings is driven by the increasing demand for high precision and durable bearings in the industrial sector. The growing need for automation and robotics in manufacturing and assembly processes has led to the widespread adoption of Cross Roller Bearings. Additionally, the rising investments in infrastructure development and construction activities are expected to further fuel the demand for Cross Roller Bearings in the coming years.The report on the global Cross Roller Bearings market provides a comprehensive analysis of the key market trends, drivers, restraints, and opportunities. It also includes a detailed segmental analysis, highlighting the growth prospects of different application areas and regions. The report also profiles the leading players in the market and provides an in-depth analysis of their product offerings, market strategies, and competitive landscape.One of the key players in the global Cross Roller Bearings market is (company name), a leading manufacturer of high-quality precision bearings. (company name) is renowned for its innovative and technologically advanced products that meet the highest standards of quality and performance. The company offers a wide range of Cross Roller Bearings that are designed to meet the specific requirements of different industrial applications.With a strong focus on research and development, (company name) continuously strives to introduce new and improved products to meet the evolving needs of its customers. The company's state-of-the-art manufacturing facilities and stringent quality control measures ensure that its Cross Roller Bearings are of the highest quality and reliability. (company name) also emphasizes on providing excellent customer support and after-sales service, establishing itself as a trusted partner for its clients.The global Cross Roller Bearings market is highly competitive, with several established players competing for market share. In this dynamic landscape, (company name) has maintained a leading position through its commitment to innovation, quality, and customer satisfaction. The company's strong global presence and distribution network enable it to effectively serve customers across different regions and industries.As the demand for high precision bearings continues to rise, (company name) remains focused on expanding its product portfolio and enhancing its manufacturing capabilities. The company is also investing in research and development to develop advanced bearing technologies that offer superior performance and durability. With a strong emphasis on sustainability, (company name) is also exploring eco-friendly manufacturing processes and materials to minimize its environmental impact.In conclusion, the global Cross Roller Bearings market is poised for significant growth in the coming years, driven by the increasing demand for high precision and durable bearings. (company name) is well-positioned to capitalize on this growth with its innovative products, strong market presence, and commitment to quality. As the industry continues to evolve, (company name) is dedicated to remaining at the forefront of technological advancements and meeting the needs of its customers with unparalleled precision bearings.