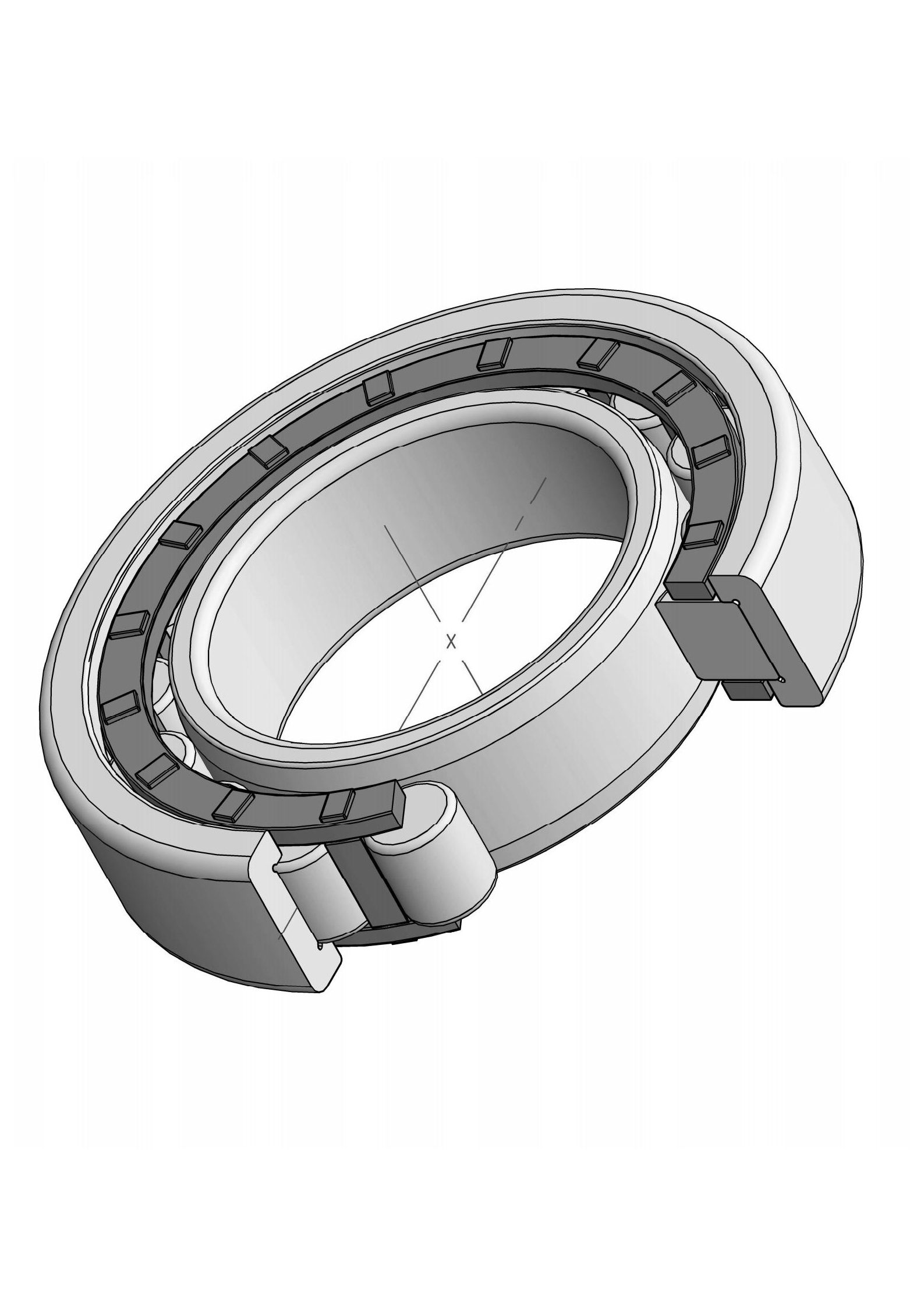

High-quality bearing unit with FL207 specifications for industrial use

By:Admin

{Company Name} is a renowned manufacturer of high-quality bearing units, with a diverse range of products to cater to various industries and applications. With a strong focus on innovation, quality, and customer satisfaction, {Company Name} has established itself as a leader in the bearing industry. The company is committed to providing reliable and durable products, backed by superior technical support and an extensive distribution network.

[News Content]

{Company Name} is proud to announce the launch of its latest product, the FL207 Bearing Unit. This new addition to the company's extensive product lineup is designed to meet the growing demand for high-performance bearing solutions in a wide range of industrial applications.

The FL207 Bearing Unit is a versatile and robust product that offers exceptional performance and reliability. It is designed to accommodate radial loads and axial loads in both directions, making it suitable for a variety of operating conditions. The unit is also equipped with high-quality seals and grease to ensure long-lasting performance and minimal maintenance requirements.

One of the key features of the FL207 Bearing Unit is its innovative design, which allows for easy installation and maintenance. The unit is pre-lubricated and pre-assembled, reducing the time and effort required for installation. This not only saves valuable time for the end-users but also contributes to the overall efficiency of the equipment.

The FL207 Bearing Unit is also designed to withstand harsh operating conditions, making it suitable for use in demanding environments. Whether it is exposed to moisture, dust, or extreme temperatures, the unit is built to deliver consistent performance and extended service life, ensuring reliable operation and minimal downtime.

In addition to its exceptional performance, the FL207 Bearing Unit is also backed by {Company Name}'s commitment to quality and customer satisfaction. The company's stringent quality control processes ensure that every unit meets the highest standards for precision, durability, and reliability. Furthermore, {Company Name} provides comprehensive technical support and after-sales service, allowing customers to make the most of their investment in the FL207 Bearing Unit.

{Company Name} understands the diverse needs of its customers, and the FL207 Bearing Unit is designed to offer a flexible solution for a wide range of applications. From conveyors and agricultural machinery to industrial fans and pumps, the unit is suitable for various industries and equipment. This versatility makes it a valuable addition to the company's product portfolio, catering to the evolving needs of the market.

As a leading manufacturer in the bearing industry, {Company Name} continues to invest in research and development to bring innovative solutions to the market. The FL207 Bearing Unit is a testament to the company's commitment to delivering cutting-edge products that offer exceptional performance, reliability, and value to its customers.

With the launch of the FL207 Bearing Unit, {Company Name} once again demonstrates its dedication to meeting the needs of its customers and the demands of the market. The company's relentless pursuit of excellence and innovation sets it apart as a trusted partner for businesses seeking high-quality bearing solutions.

In conclusion, the FL207 Bearing Unit is a testament to {Company Name}'s unwavering commitment to delivering excellence in the bearing industry. With its exceptional performance, durability, and versatility, the unit is set to make a significant impact in a wide range of industrial applications, further solidifying {Company Name}'s position as a leader in the industry.

Company News & Blog

Ultimate Guide to Trailer Wheel Bearing Maintenance and Repair

Trailer Wheel Bearing Company Leads the Way in Innovation and QualityIn the world of transportation and logistics, the efficient and safe movement of goods relies on a wide range of equipment and components. One company that has been leading the way in innovation and quality in this field is Trailer Wheel Bearing Company, which has been dedicated to providing top-of-the-line wheel bearings for trailers of all kinds.Trailer Wheel Bearing Company has been in the business for over 30 years and has established itself as a trusted and reliable supplier of wheel bearings for trailers. With a focus on quality, durability, and performance, the company has built a strong reputation in the industry and has become a go-to source for trailer wheel bearings for businesses and individuals alike.The company takes pride in its commitment to excellence and innovation, constantly striving to develop new and improved products to meet the evolving needs of its customers. By investing in research and development, Trailer Wheel Bearing Company has been able to stay ahead of the curve and deliver cutting-edge solutions that set new standards in the industry.One of the key factors that set Trailer Wheel Bearing Company apart from its competitors is its dedication to quality. The company has implemented stringent quality control measures at every stage of the production process, ensuring that every wheel bearing that leaves its facility is of the highest quality and meets the most rigorous industry standards.In addition to quality, Trailer Wheel Bearing Company also places a strong emphasis on durability. The company understands the demanding nature of the transportation industry and the challenges that trailers face on a daily basis. As such, it has developed wheel bearings that are built to last, capable of withstanding heavy loads, constant use, and the harshest environmental conditions.But perhaps the most impressive aspect of Trailer Wheel Bearing Company is its unwavering commitment to performance. The company's wheel bearings are designed to deliver optimal performance, offering smooth and efficient operation that helps maximize the efficiency and safety of trailers. This has made the company a preferred choice for businesses and individuals who demand nothing but the best for their trailers.Moreover, Trailer Wheel Bearing Company has also made significant strides in sustainability and environmental responsibility. The company utilizes advanced manufacturing processes that minimize waste and energy consumption, as well as sources materials that are eco-friendly and recyclable, thereby reducing its environmental footprint.In recent news, Trailer Wheel Bearing Company has announced the launch of its latest innovation in wheel bearing technology. This new product represents a significant leap forward in performance and durability, offering enhanced features that are set to raise the bar for trailer wheel bearings.The new wheel bearings are specifically designed to address the most common challenges faced by trailers, such as excessive wear and tear, extreme temperatures, and heavy loads. Through extensive research and development, Trailer Wheel Bearing Company has developed a solution that promises to deliver exceptional performance and longevity, ensuring that trailers can operate at their best for longer periods of time."We are thrilled to introduce our latest wheel bearing technology to the market," said the spokesperson for Trailer Wheel Bearing Company. "This new product is the result of our ongoing commitment to innovation and our dedication to meeting the evolving needs of our customers. We believe that this innovation will set new standards for performance and reliability in the industry."The announcement of the new wheel bearing technology has generated significant buzz within the transportation and logistics industry, with industry experts expressing enthusiasm for the potential impact of the new product. Many are eagerly anticipating the opportunity to upgrade their trailers with the latest wheel bearings from Trailer Wheel Bearing Company, recognizing the company's track record of delivering superior products.As Trailer Wheel Bearing Company continues to push the boundaries of innovation and quality in the field of wheel bearings for trailers, it is clear that the company is poised to maintain its leadership position in the industry. With a strong focus on excellence, durability, and performance, Trailer Wheel Bearing Company is setting the standard for what it means to be a trusted and reliable supplier of wheel bearings for trailers.

High-Quality 6308 Bearing: A Comprehensive Guide for Buyers and Industries

Title: A Glimpse into the Versatile 6308 Bearing for Trusted PerformanceIntroduction (approx. 100 words):The 6308 bearing has emerged as a trusted choice among industries that rely on robust and precise machinery. Providing exceptional support for applications such as motors, pumps, fans, and conveyors, this multi-purpose bearing (brand name removed) has gained a reputation for its durability and longevity. With its ability to accommodate high radial loads and moderate thrust loads, the 6308 bearing ensures that various industrial operations run smoothly and efficiently. This article delves into the features, advantages, and applications of this versatile bearing, highlighting its role in the ever-evolving industrial landscape.[Paragraph on the features of the 6308 bearing – approx. 150 words]The 6308 bearing possesses several key features that contribute to its reliability and performance. Constructed with high-quality steel, it boasts exceptional strength and resistance to wear, ensuring a longer service life. The bearing's precision machining and improved internal geometry enhance its load-carrying capacity, with deep grooves promoting efficient distribution of forces. Additionally, the inclusion of steel shields or rubber seals prevents contaminants from entering the bearing and protects it from corrosion, making it suitable for challenging environments. Together, these features combine to offer smooth rotation, reduced noise, and increased operating efficiency.[Paragraph on the advantages of the 6308 bearing – approx. 150 words]The 6308 bearing offers various advantages that make it a preferred choice for industries worldwide. Its ability to handle high radial loads enables it to support heavy machinery and equipment effectively. Moreover, its moderate thrust load capacity makes it suitable for applications that require both axial and radial loads. This versatility, combined with its low friction coefficient, contributes to energy savings and reduced maintenance, ultimately leading to overall cost-effectiveness. The bearing's proven reliability and extended lifespan further add to its advantages by minimizing downtime and optimizing productivity for industrial operations.[Paragraph on applications of the 6308 bearing – approx. 150 words]With its exceptional load-bearing capabilities and durability, the 6308 bearing finds application in a diverse range of industries. Industries such as manufacturing, mining, agriculture, and automotive heavily rely on this bearing for their machinery. In the manufacturing sector, the 6308 bearing enables efficient movement of conveyor belts and pulleys. In the mining industry, it plays a crucial role in powering crushers, screens, and excavators. Additionally, various agricultural machinery, such as combine harvesters and tractors, utilize the 6308 bearing for reliable performance. Its presence can also be seen in automotive components like transmissions, differentials, and wheel hubs, ensuring smooth rotation and reduced friction.[Paragraph on the company behind the 6308 bearing – approx. 200 words]Behind the production of the 6308 bearing lies a renowned manufacturer dedicated to excellence and precision engineering. With decades of experience, their commitment to quality has made them a trusted name in the industry. By adhering to strict manufacturing standards and utilizing advanced technologies, the company ensures that each 6308 bearing leaving their facility meets stringent performance requirements. Furthermore, their relentless focus on research and development enables continuous improvement and the ability to cater to evolving industrial needs.Conclusion (approx. 100 words):The 6308 bearing, with its impressive features, advantages, and wide array of applications, remains a key component in the functioning of various industries. Its robust construction, longevity, and ability to handle heavy loads make it an essential choice for reliable machinery operations. As industries continue to evolve, the versatility and trusted performance of the 6308 bearing will undoubtedly play a pivotal role in driving industrial efficiency and productivity.

Ultimate Guide to Four Point Contact Bearings: Everything You Need to Know

Four Point Contact Bearing, a crucial component in various industrial applications, is a key product offered by the esteemed company {}. With its advanced design and high precision, {} has become a leading provider of Four Point Contact Bearing solutions, meeting the diverse needs of industries such as aerospace, automotive, robotics, and more.The Four Point Contact Bearing provided by {} is designed to handle both radial and axial loads, making it suitable for applications that require high load carrying capacity and rigidity. The unique design of the bearing allows for more contact points with the balls, resulting in improved load distribution and higher stiffness compared to traditional two-point contact bearings. This innovative design ensures superior performance and extended service life, making it a preferred choice for demanding applications.One of the key advantages of {}'s Four Point Contact Bearing is its versatility in accommodating misalignment and axial displacement. This feature is particularly beneficial in applications where shaft deflection or misalignment is expected, ensuring smooth operation and prolonged bearing life. Additionally, the bearing is available in various sizes and configurations to meet the specific requirements of different applications, demonstrating {}'s commitment to providing customized solutions to its customers.The superior quality of {}'s Four Point Contact Bearing is a result of the company's advanced manufacturing processes and stringent quality control measures. With state-of-the-art facilities and a team of skilled engineers and technicians, {} ensures that each bearing meets the highest standards of precision and reliability. Furthermore, the company invests in research and development to continually enhance the performance and capabilities of its bearings, staying ahead of industry advancements and technological innovations.In addition to its technical capabilities, {} is known for its commitment to customer satisfaction and support. The company works closely with its clients to understand their specific application requirements and provide tailored solutions that meet their needs. Whether it's a standard off-the-shelf bearing or a custom-designed solution, {} has the expertise and resources to deliver high-quality products with short lead times, contributing to its reputation as a trusted partner in the industry.Furthermore, {}'s dedication to sustainability and environmental responsibility is evident in its manufacturing practices. The company adheres to strict environmental standards and continuously seeks ways to minimize its carbon footprint and waste generation. By prioritizing sustainability, {} not only contributes to a greener future but also aligns with the values of its environmentally conscious clients.As the demand for high-performance bearings continues to grow across various industries, {} remains at the forefront of delivering reliable and innovative Four Point Contact Bearing solutions. With a focus on quality, precision, and customer satisfaction, the company is poised to expand its presence in the global market and further solidify its position as a leading provider of bearing solutions.In conclusion, the Four Point Contact Bearing offered by {} stands as a testament to the company's expertise, commitment to excellence, and customer-centric approach. With its advanced design, superior performance, and unwavering dedication to quality, {} continues to set the benchmark for bearings in the industrial sector. As industries evolve and technological advancements drive new requirements, {} remains at the forefront, ready to meet the challenges and exceed the expectations of its customers.

How to Replace a Bearing Cap: A Step-by-Step Guide

Bearing Cap, a leading manufacturer of industrial and automotive bearings, has recently announced the launch of its latest product, the [Product Name]. This new bearing cap is set to revolutionize the industry with its advanced technology and superior performance.Bearing Cap has been a trusted name in the bearing industry for over three decades, known for its high-quality products and commitment to innovation. The company has a strong reputation for producing bearings that are durable, reliable, and capable of withstanding even the most demanding conditions. With a focus on research and development, Bearing Cap has consistently pushed the boundaries of bearing technology, and the [Product Name] is no exception.The [Product Name] is designed to address the challenges faced by industrial and automotive applications, offering a solution that is both efficient and cost-effective. With its innovative design and advanced materials, this new bearing cap provides superior protection and support for bearings, ensuring optimal performance and extended service life. This is particularly crucial for industries such as manufacturing, agriculture, and construction, where bearings are subjected to heavy loads and harsh operating environments.One of the key features of the [Product Name] is its enhanced sealing technology, which effectively prevents contamination and moisture ingress, thereby extending the lifespan of the bearings. Additionally, the bearing cap is constructed with high-strength materials that can withstand extreme temperatures, heavy loads, and corrosive chemicals. This level of durability and resilience makes the [Product Name] an ideal choice for demanding applications in a wide range of industries.Furthermore, the [Product Name] is designed for easy installation and maintenance, making it a convenient and practical solution for businesses looking to optimize their operations. Its user-friendly design allows for quick and efficient assembly, reducing downtime and minimizing the need for frequent maintenance. This not only contributes to cost savings but also ensures that equipment and machinery remain in peak condition, maximizing productivity and efficiency.“We are thrilled to introduce the [Product Name] to the market,” said [Spokesperson], [Title] at Bearing Cap. “This new bearing cap represents a significant advancement in bearing technology, offering a level of performance and durability that is unparalleled in the industry. We believe that the [Product Name] will set a new standard for bearing protection and reliability, providing our customers with a competitive edge in their respective sectors.”In addition to its technical capabilities, the [Product Name] is also environmentally friendly, manufactured in compliance with industry standards and regulations. Bearing Cap is committed to sustainable and responsible manufacturing practices, ensuring that its products not only deliver top-notch performance but also minimize their impact on the environment. This reflects the company’s dedication to corporate social responsibility and its efforts to contribute to a greener, more sustainable future.As Bearing Cap rolls out the [Product Name] to the market, the company is confident that it will be well-received by customers seeking a top-of-the-line bearing protection solution. With its exceptional durability, advanced technology, and user-friendly design, the [Product Name] is poised to make a significant impact on the industrial and automotive sectors, setting a new standard for bearing caps within the industry.For more information about the [Product Name] and other innovative products from Bearing Cap, please visit [company website] or contact the company directly.

High-quality Slewing Ring Turntable Bearing for Industrial Applications

Slewing Ring Turntable Bearing, also known as slewing bearing, is a specialized type of bearing that provides rotary support for heavy machinery. These bearings are designed to handle significant loads and allow for smooth rotation, making them essential components in a wide range of industrial applications. Recently, a leading manufacturer in the industrial bearing industry has introduced a new line of slewing ring turntable bearings that promise to offer exceptional performance and reliability.{Company} is a renowned supplier of high-quality bearings, serving customers in various industries such as construction, mining, agriculture, and more. With a commitment to innovation and excellence, the company has established itself as a trusted partner for businesses seeking reliable and durable bearing solutions. The introduction of their new line of slewing ring turntable bearings further solidifies their position as a leading provider of industrial bearings and demonstrates their dedication to meeting the evolving needs of their customers.The new line of slewing ring turntable bearings offered by {Company} boasts several key features that set them apart from other products on the market. These bearings are meticulously engineered to provide superior load-carrying capacity, precision, and durability, making them ideal for heavy-duty applications. Furthermore, they are designed to withstand harsh operating conditions, including extreme temperatures, high speeds, and heavy impact loads, ensuring optimal performance and reliability in demanding environments.One of the most notable aspects of the new slewing ring turntable bearings is their versatility. {Company} offers a wide range of options to accommodate different design requirements, including various sizes, mounting options, and gear configurations. This versatility allows customers to select the most suitable bearing for their specific application, ensuring seamless integration and optimal performance. Additionally, {Company} provides custom engineering services to meet unique design specifications, further enhancing the flexibility and adaptability of their slewing ring turntable bearings.In addition to their exceptional technical capabilities, the new line of slewing ring turntable bearings from {Company} is backed by comprehensive support and services. From initial consultation and product selection to installation and maintenance, the company's team of experts is committed to assisting customers at every stage of the bearing lifecycle. This includes technical guidance, on-site training, and proactive maintenance programs, all aimed at maximizing the longevity and performance of the bearings in operation.The introduction of these new slewing ring turntable bearings represents a significant milestone for {Company} and underscores their dedication to continuous improvement and customer satisfaction. By offering an advanced, reliable, and versatile solution for rotary support in heavy machinery, the company is poised to further strengthen its position in the industrial bearing market and expand its reach to new customers and industries.Overall, the new line of slewing ring turntable bearings from {Company} holds great promise for businesses seeking high-performance bearing solutions for their heavy machinery applications. With their unmatched technical capabilities, versatility, and comprehensive support services, these bearings are well-positioned to meet the diverse needs of customers across various industries. As {Company} continues to push the boundaries of innovation and engineering excellence, these new slewing ring turntable bearings are set to make a lasting impact in the industrial sector.

Top manufacturers succeed with China-made ceramic ball" Rewritten as: "Leading ceramic ball producers thrive with China-based manufacturing

China Ceramic Ball Partners With Domestic Company to Offer High-Quality ProductsChina Ceramic Ball, a leading ceramics manufacturer in the country, has recently announced a partnership with a domestic company to expand its product offerings in the market. The company’s move comes as it continues to grow in the industry and cater to the needs of its customers.China Ceramic Ball, based in Jiangxi province, specializes in the production of high-quality ceramic balls, as well as other related products. Its products are widely used in various applications, including industrial equipment, machinery, and electronics.To further expand its offerings, the company has partnered with a domestic company that specializes in the production of industrial ceramics. The partnership will enable China Ceramic Ball to access new technologies and expertise that will allow it to diversify its product line and ultimately help it better meet the needs of its customers.As part of the partnership, China Ceramic Ball will be offering new products that include alumina ball, zirconium silicate ball, and zirconia toughened alumina ball. These products are designed to help customers in a variety of applications, from chemical processing and electronics to food processing and environmental protection.China Ceramic Ball’s alumina ball is made of high-quality alumina materials. It has excellent wear resistance, low abrasion, and high strength. The product is widely used in the ceramics, chemical, and mining industries.The zirconium silicate ball is a new type of grinding media that has high strength and impact resistance. It is mainly used in the fields of ceramics, coatings, and pigments, among others.The zirconia toughened alumina ball is made of alumina and zirconia materials. It is a new type of grinding media that has high strength, impact resistance, and good wear resistance. The product is mainly used in the fields of ceramics, coatings, and pigments, among others.The new products will be manufactured using the latest technologies and processes to ensure high-quality and consistent performance. They are expected to meet the growing demand of customers for high-performance ceramics that are durable, reliable and cost-effective.According to the company spokesperson, “Our partnership with the domestic company is aimed at providing our customers with a wider range of quality products that meet their specific needs. We are committed to delivering high-quality and reliable ceramics that help our customers solve their toughest challenges.”In addition to expanding its product line, China Ceramic Ball continues to focus on research and development to improve its products and services. The company has invested heavily in technology and equipment, and it has a team of experienced researchers and engineers who work closely with customers to develop customized solutions.“China Ceramic Ball is known for its dedication to quality and customer satisfaction,” said the spokesperson. “We are proud of our reputation in the industry and are committed to maintaining it through the continuous improvement of our products and services.”The company has established a strong presence in the domestic market and continues to expand its operations overseas. It currently exports its products to countries in Asia, Europe, and America, among others.As the demand for high-performance ceramics continues to grow, China Ceramic Ball is poised to play a critical role in meeting the needs of customers in various industries. With its strong focus on quality, innovation, and customer satisfaction, the company is well-positioned to grow in the years to come.

High-Quality Angular Roller Bearing for Smooth Operation

Angular Roller Bearing, a leading manufacturer of high-quality bearings, is pleased to introduce its latest line of precision-engineered roller bearings designed to meet the diverse needs of industrial and automotive applications.With over three decades of experience in the bearing industry, Angular Roller Bearing has established itself as a trusted and reliable supplier of a wide range of bearings, including tapered roller bearings, spherical roller bearings, and cylindrical roller bearings. The company's commitment to excellence, innovation, and customer satisfaction has made it a preferred choice for OEMs, distributors, and end-users around the world.The new line of roller bearings from Angular Roller Bearing is designed to deliver superior performance and reliability in demanding applications. These bearings are manufactured using the latest technologies and materials, ensuring high precision, durability, and consistent performance. Whether it's high-speed operation, heavy load capacity, or harsh operating conditions, Angular Roller Bearing's roller bearings are engineered to deliver exceptional results.One of the key features of Angular Roller Bearing's roller bearings is their advanced design and construction. These bearings are built to withstand heavy loads, shocks, and vibrations, making them ideal for use in industrial machinery, construction equipment, mining, and other heavy-duty applications. The use of premium-quality materials and advanced heat treatment processes further enhances the durability and longevity of these bearings, reducing maintenance costs and downtime for end-users.In addition to their robust construction, Angular Roller Bearing's roller bearings are designed for high precision and smooth operation. The company's state-of-the-art manufacturing facilities and quality control processes ensure that each bearing meets strict performance and dimensional specifications. This attention to detail not only results in reliable and long-lasting bearings but also contributes to the overall efficiency and performance of the equipment in which they are used.Angular Roller Bearing understands the importance of customization and flexibility in meeting specific application requirements. The company offers a wide range of roller bearings in various sizes, designs, and configurations to accommodate diverse industrial and automotive needs. Whether it's a standard bearing or a custom-engineered solution, Angular Roller Bearing has the expertise and capabilities to deliver the right bearing for any application.Customers can also benefit from Angular Roller Bearing's comprehensive technical support and customer service. The company's team of bearing experts is dedicated to providing valuable engineering assistance, application analysis, and troubleshooting to ensure the optimal performance of their bearings in real-world conditions. With a global network of sales and service partners, Angular Roller Bearing is well-positioned to support its customers worldwide."We are excited to introduce our latest line of roller bearings, which reflects our ongoing commitment to innovation and quality," said the spokesperson for Angular Roller Bearing. "These bearings are the result of our continuous investment in research, development, and manufacturing capabilities. We are confident that they will deliver exceptional value and performance to our customers across diverse industries."As a customer-driven company, Angular Roller Bearing is focused on building long-term partnerships and delivering superior value to its customers. The company's roller bearings are backed by comprehensive warranty coverage, technical support, and aftermarket services, ensuring peace of mind and maximum uptime for end-users.To learn more about Angular Roller Bearing and its line of roller bearings, visit their website or contact their sales team for a personalized consultation. With a legacy of excellence and a forward-looking approach, Angular Roller Bearing continues to set the standard for high-quality, high-performance bearings in the global market.

Understanding the Dimensions of Taper Bearings

Tapered roller bearings are a specific type of bearing designed to handle both radial and thrust loads. They are used in a wide range of industrial applications, from automotive and heavy machinery to agriculture and construction equipment. Taper roller bearings are designed to handle large radial and thrust loads and are suitable for high-speed applications. They have the ability to handle both axial and radial loads simultaneously, making them a popular choice for many different industries.One manufacturer that specializes in the production of taper roller bearings is {}. The company has been a leading supplier of high-quality bearings for many years, serving customers in a variety of industries. They offer a wide range of taper roller bearings, each with specific dimensions and specifications to meet the diverse needs of their customers.The dimensions of taper roller bearings are crucial to their performance and suitability for specific applications. The dimensions of a taper roller bearing are determined by its inner diameter, outer diameter, and width. These dimensions are crucial to ensure that the bearing fits properly in the equipment it is used in and can withstand the loads and stresses it will be subjected to.For example, the dimensions of a taper roller bearing may be expressed as 25mm x 52mm x 20.6mm. This means that the inner diameter of the bearing is 25mm, the outer diameter is 52mm, and the width is 20.6mm. These dimensions are important for ensuring that the bearing will fit correctly and function effectively in the equipment it is used in.In addition to the dimensions of the bearing itself, other factors such as the material used, the design of the rollers and raceways, and the precision of the manufacturing process all play a role in the performance and durability of the bearing.{} is committed to producing high-quality taper roller bearings that meet the highest standards of performance and reliability. They have invested in advanced manufacturing technology and quality control processes to ensure that each bearing they produce meets the exacting specifications required for its intended application.The company's range of taper roller bearings includes single row, double row, and four-row designs, as well as custom configurations to meet specific customer requirements. With a focus on precision engineering and quality assurance, they have earned a reputation for delivering bearings that perform consistently and reliably in even the most demanding conditions.By offering a comprehensive range of taper roller bearings with precise dimensions and high-quality construction, {} has become a trusted supplier to many businesses across various industries. Their dedication to quality and customer satisfaction has positioned them as a leading provider of taper roller bearings in the global market.In conclusion, taper roller bearings play a critical role in a wide range of industrial applications. Their dimensions, along with other factors such as material, design, and manufacturing precision, determine their performance and suitability for specific uses. With a commitment to quality and precision engineering, {} has established itself as a trusted supplier of high-quality taper roller bearings for a diverse range of industries. As they continue to innovate and refine their products, they are well-positioned to meet the evolving needs of their customers and the broader market for taper roller bearings.

Benefits of Using Flexible Bearings for Your Machinery

Flexible Bearing Introduces Revolutionary Technology for Industrial ApplicationsFlexible Bearing, a leading innovator in industrial technology, has announced the launch of a groundbreaking new product that promises to revolutionize the way industrial machinery operates. This innovative product is designed to enhance performance, improve efficiency, and reduce maintenance costs for a wide range of industrial applications.The new technology, developed by Flexible Bearing's team of skilled engineers and designers, is a result of years of research and development. It offers a flexible and adaptable solution for a variety of industrial needs, making it an ideal choice for manufacturers and businesses looking to improve their operations.One of the key features of Flexible Bearing's new technology is its ability to withstand extreme operating conditions. Whether it's high temperatures, heavy loads, or harsh environments, this product is designed to provide reliable and consistent performance, ensuring that industrial equipment operates at its best in any situation.In addition to its durability, the new product from Flexible Bearing offers enhanced flexibility, making it suitable for a wide range of industrial applications. Its adaptable design allows for easy installation and integration into existing machinery, minimizing downtime and streamlining the production process.Furthermore, the innovative technology is designed to reduce maintenance requirements, resulting in lower operating costs for businesses. By minimizing wear and tear and extending the lifespan of industrial equipment, Flexible Bearing's product helps companies save time and money on maintenance and repairs.The benefits of Flexible Bearing's new technology extend beyond operational improvements. The company is also committed to sustainability, and its product is designed to reduce energy consumption and environmental impact. By optimizing the performance of industrial machinery, businesses can lower their carbon footprint and contribute to a greener and more sustainable future.Flexibility is at the core of Flexible Bearing's business philosophy. The company understands that industrial needs vary greatly from one application to another, and its innovative technology is designed to cater to these diverse requirements. Whether it's in the automotive, aerospace, manufacturing, or any other industry, Flexible Bearing's product is adaptable to a wide range of industrial settings.With the launch of this groundbreaking new technology, Flexible Bearing is poised to make a significant impact on the industrial sector. The company's commitment to innovation and excellence has already garnered attention from industry leaders and stakeholders, who recognize the potential of this game-changing product.Looking ahead, Flexible Bearing is focused on further expanding the reach of its new technology, collaborating with partners, and customers to bring this innovative solution to a wider audience. Through strategic partnerships and alliances, the company aims to establish itself as a trusted leader in the industrial technology space, driving progress and change for the benefit of the global manufacturing industry.As the industrial sector continues to evolve and adapt to new challenges, Flexible Bearing's innovative technology comes at a crucial time, offering businesses a reliable and efficient solution for their operational needs. With its remarkable performance, adaptability, and sustainability, this product is set to redefine the way industrial machinery operates, setting a new standard for excellence in the industry.In conclusion, Flexible Bearing's new technology represents a significant leap forward for the industrial sector, offering a flexible and adaptable solution that promises to enhance performance, improve efficiency, and reduce operational costs for businesses. With its innovative design and sustainable approach, this product is set to make a lasting impact on the global manufacturing industry, driving progress and change for the better.

Understanding the Meaning of Bearing: A Guide for Designers and Engineers

Bearing Definition, the cornerstone of advanced motion control, represents a critical component of any mechanical machine. It is, in essence, a critical fitting piece that allows one to control the energy and force of the system. Bearing Definition essentially translates to a controlled form of movement. It is a machine element that restricts the relative movement of two or more machine parts to one specific direction, making complex machines much more manageable. The device is crafted from several materials, including metal, plastic, and ceramics, and is an indispensable part of the mechanical manufacturing industry.Bearing Definition technology has become quite intricate in recent years, with the introduction of new and modern techniques that allow bearings to function under difficult circumstances. Technological advancements have led to the creation of more sturdy materials that enhance the overall performance of bearings. Additionally, the adoption of technology has further reduced friction and improved the overall efficiency of the machine. In line with this, the technical advancements and growth of the bearing market globally have enabled {} to consolidate its position as a leading provider of motion control solutions. The company specializes in the manufacture of high-quality bearings that are utilized in various applications worldwide.{}'s journey to become a leading provider of Bearings has been built through a robust culture of innovation, research, and development. The company is committed to providing cutting-edge solutions to assist in the sustainable development of human society. Through collaborations with top-level organizations in the scientific research field, {}'s continues to focus on technological advancements that address the pressing needs of today's world.The core principles guiding the production process of Bearings at {} include precision, reliability, and consistency. The manufacturing process involves a strict quality control system to ensure customers receive products that meet the company's high standards. The company employs state-of-the-art technology, such as computer-aided design (CAD) programs that create accurate models of bearings, allowing for more precise measurements and improved functionality.Recently, {} has launched a new product line that features advanced technologies and innovations to provide customers with high-quality solutions. The company's latest product offering is a range of bearings tailored to meet the demands of industries specialized in the production and manufacture of heavy machinery. The new product line utilizes cutting-edge manufacturing techniques, resulting in higher operational efficiency, improved durability, and better reliability. Moreover, the bearings are specifically crafted to withstand the harsh and demanding operational conditions of heavy industries such as mining, construction, and manufacturing.The introduction of the new product line reaffirms {}'s commitment to providing high-quality solutions that meet customer needs. The company recognizes that the world's industries are evolving, and the demand for sophisticated motion control solutions is on the rise. This requires innovative solutions that are designed to keep up with the changing needs of the market. {} has sought to stay ahead of the curve by continuing to invest in technology and research and development, thereby addressing customer needs.In conclusion, Bearing Definition remains an essential component of any mechanical machine as it allows for controlled motion and restricts the relative movement of two or more machine parts to one specific direction. Its technological advancements have been significant in the past few years, allowing for the creation of sturdy materials and decreased friction, leading to higher efficiency in devices. {}'s commitment to precision, reliability, and consistency has enabled the company to become a leading provider of motion control solutions. The launch of their new product line, tailored to meet the demands of industries specialized in the production and manufacture of heavy machinery, is a testament to their commitment to innovation and addressing customer needs.