Revolutionary Rubber Shield Bearing: An Innovative Solution for Enhanced Performance

By:Admin

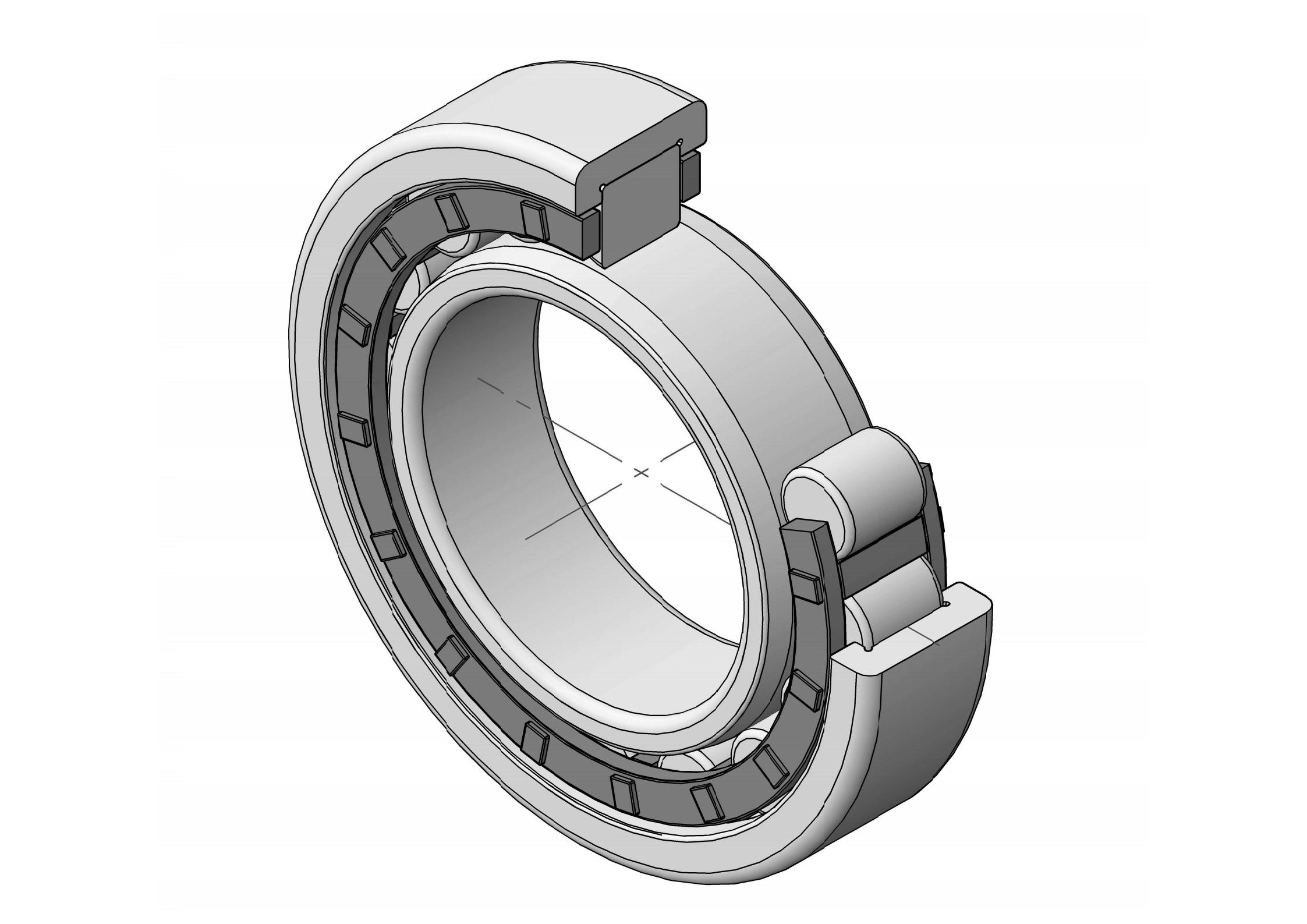

In the world today, mechanical engineering has become a core aspect of our daily lives. This is because mechanical systems power virtually every industry that we rely on, from transportation to manufacturing and heavy construction to mining. For these applications, the performance and reliability of equipment are critical to productivity, safety, and cost-effectiveness. One component that plays a vital role in this equation is the bearing. Bearings support the rotating parts of machines, preventing friction and wear, and ensuring smooth operation. In recent years, there has been a growing demand for bearings that can withstand heavy loads, high speeds, and harsh environments. One solution that has stood the test of time is the Rubber Shield Bearing.

Rubber Shield Bearing is an innovative type of bearing that has been engineered to deliver excellent performance and longevity. Unlike traditional bearings that rely on metal-to-metal contact, Rubber Shield Bearings feature a layer of high-quality synthetic rubber that acts as a protective shield. This rubber layer not only prevents the ingress of contaminants like dirt, dust, and moisture, but it also reduces noise and vibration levels. This makes Rubber Shield Bearings ideal for applications where precision, durability, and quiet operation are crucial.

One company that has made a name for itself in the Rubber Shield Bearing market is {remove brand name}, a leading manufacturer of bearings and related components. Founded in {insert date}, {remove brand name} has been at the forefront of innovation, quality, and customer satisfaction. With a strong commitment to research and development, the company has developed a broad range of products that cater to diverse and specialized applications. Over the years, {remove brand name} has built a reputation for its expertise in designing and producing high-performance bearings, including Rubber Shield Bearings.

What sets {remove brand name}'s Rubber Shield Bearings apart is their superior engineering and construction. These bearings are manufactured using premium-grade materials, such as chrome steel, high-strength polymers, and resilient rubber compounds. They are designed to endure extreme loads, temperatures, speeds, and pressures, without sacrificing efficiency or reliability. Whether it's in heavy machinery, transportation, energy, or aerospace applications, {remove brand name}'s Rubber Shield Bearings are a dependable choice.

In addition to their durability and longevity, Rubber Shield Bearings offer several benefits that make them a top choice for engineers and operators. Firstly, their rubber shield protects the bearing from contaminants and premature wear, ensuring that it continues to operate smoothly even in harsh environments. Secondly, the rubber shield also acts as a noise and vibration damper, reducing the overall noise levels of the machine and improving comfort for operators and nearby personnel. Thirdly, the rubber shield provides a seal that extends the service life of the bearing, reducing maintenance costs, and downtime. Fourthly, Rubber Shield Bearings are easy to install, maintain, and repair, making them a cost-effective solution for businesses of all sizes.

Some of the applications that benefit from {remove brand name}'s Rubber Shield Bearings include construction equipment such as bulldozers, cranes, excavators, and loaders. These machines require robust and reliable bearings that can handle heavy loads, shock, and vibration. Rubber Shield Bearings are an excellent fit for these applications, as they reduce the risk of contamination, prolong the lifespan of the bearing, and improve operator comfort. Other applications that benefit from Rubber Shield Bearings include automotive and rail transportation, energy generation, mining, and agriculture.

In conclusion, Rubber Shield Bearing is a game-changer in the world of mechanical engineering. They offer superior performance, longevity, and reliability in some of the most demanding applications. {remove brand name} is a leading manufacturer of Rubber Shield Bearings, offering high-quality products that meet the needs of customers across various industries. With their innovative design, premium-grade materials, and commitment to excellence, {remove brand name}'s Rubber Shield Bearings are an investment that pays off in the long run.

Company News & Blog

High-Quality 6302 2RS Bearings: A Comprehensive Guide to Understanding and Choosing the Best Option

In today's modern world, the need for high-quality bearings has become more prevalent than ever before. These tiny components play a vital role in the functioning of machines used in various industries. Be it the automobile sector, construction, aviation, or manufacturing, bearings are an essential component that cannot be overlooked. The 6302 2RS bearing, a product that has become increasingly popular in recent years, is now available through a company that is committed to providing top-tier quality and service.This 6302 2RS bearing is a ball bearing that has been designed to withhold high radial loads and moderate axial loads in both directions. The famous "2RS" tag on it denotes that this bearing is of a two rubber seal type, which significantly improves the performance of the bearing and protects it against contaminants and moisture. These features make the 6302 2RS bearing the perfect choice for use in automotive engines, gearboxes, electric motors, pumps, and several other applications that require high radial loads.The company behind this product has been in the market for several years and has established itself as a trusted provider of high-quality bearings. They have a team of experienced professionals who are dedicated to providing the best possible service and ensuring that customers' needs are met. In addition to the 6302 2RS bearing, this company offers a wide range of bearings, including deep groove ball bearings, tapered roller bearings, and cylindrical roller bearings.One of the essential factors that set the 6302 2RS bearing offered by the company apart from its competition is the quality of the materials used in its construction. The company strives to source materials from reputable suppliers to guarantee the highest possible quality. They also conduct stringent quality checks to ensure that each bearing that leaves their warehouse meets the highest industry standards.The 6302 2RS bearing offered by this company comes in several sizes, making it a great option for different applications. Customers can place orders for bearings in bulk or as a single purchase, depending on their specific needs. The company has established an efficient logistics system that allows them to deliver orders to customers all over the world in a timely manner.In addition to providing high-quality bearings, the company is committed to offering excellent customer service. Their team of professionals is always on hand to provide assistance and guidance to customers who may be unsure about which product to choose. The company also offers technical support to help customers with any questions or concerns they may have about the product.In conclusion, the 6302 2RS bearing is an essential component that is used in various industries worldwide. This product is now available through a reputable company that is committed to providing high-quality bearings, excellent customer service, and efficient logistics. With their dedication to quality and customer satisfaction, this company has become a trusted provider of bearings in the market. So, if you're in need of a reliable and robust ball bearing, the 6302 2RS bearing offered by this company is a great option.

High quality and durable 62092rs bearing available now at competitive prices

, without using the brand name.62092rs Bearing: A Reliable and Efficient Solution for Industrial ApplicationsBearings are crucial components in various industrial applications, providing support and reducing friction between moving parts. As such, they are essential for ensuring the smooth and efficient operation of machinery and equipment. One particular type of bearing that has gained prominence in the industrial sector is the 62092rs bearing, known for its reliability and high performance.The 62092rs bearing is a deep groove ball bearing with rubber seals on both sides, designed to protect the bearing from contaminants and retain lubrication. This type of bearing is commonly used in industrial applications such as motors, pumps, and agricultural machinery, where robust performance and durability are essential.One company that specializes in the production and distribution of high-quality 62092rs bearings is {company name}. With years of experience in the industry, {company name} has established itself as a leading supplier of bearings, offering a wide range of products to meet the diverse needs of its customers.{company name} is committed to delivering the highest quality bearings to its clients, and the 62092rs bearing is no exception. Manufactured using premium-grade materials and advanced production techniques, the 62092rs bearing offered by {company name} is built to withstand the rigors of industrial environments and deliver reliable performance under demanding conditions.In addition to its exceptional quality, the 62092rs bearing provided by {company name} is also known for its efficiency and cost-effectiveness. By reducing friction and minimizing wear, this bearing helps extend the lifespan of machinery and equipment, resulting in lower maintenance costs and enhanced productivity for industrial operations.Furthermore, {company name} takes pride in its commitment to customer satisfaction, ensuring that clients receive not only top-quality products but also unparalleled service and support. The company's team of experts is readily available to provide technical guidance, assistance with product selection, and after-sales support to help customers make the most of their investment in bearings.With a focus on innovation and continuous improvement, {company name} is dedicated to staying ahead of the curve in the bearing industry. The company invests in research and development to explore new technologies and advancements in bearing design, with the aim of offering cutting-edge solutions that meet the evolving needs of its customers.As a testament to its dedication to excellence, {company name} places a strong emphasis on quality control and assurance throughout the manufacturing process. Each 62092rs bearing undergoes rigorous testing and inspection to ensure that it meets the highest standards of performance and durability, giving customers the confidence that they are investing in a reliable and long-lasting product.In conclusion, the 62092rs bearing is a key component in industrial machinery and equipment, offering reliable performance and efficiency in various applications. When sourced from a reputable and trusted supplier like {company name}, customers can expect to receive a high-quality product backed by exceptional service and support. As the industry continues to evolve, {company name} remains committed to delivering innovative bearing solutions that empower its clients to achieve their operational goals with confidence.

High-Quality 2-Bolt Flange Bearings: Everything You Need to Know

[Company Name], a leading manufacturer of industrial components, has recently introduced a new line of 2-bolt flange bearings to its extensive product offerings. These high-quality bearings are designed to provide superior support and precision for shafts and other rotating equipment in various industrial applications.The new 2-bolt flange bearings from [Company Name] are crafted with precision and expertise, using only the highest quality materials and advanced manufacturing processes. This ensures that the bearings deliver reliable performance and durability, even in the most demanding operating conditions. With a focus on innovation and continuous improvement, [Company Name] has engineered these bearings to meet the needs of modern industrial applications, helping customers optimize their equipment performance and productivity.The 2-bolt flange bearings are available in a wide range of sizes and configurations, making them suitable for diverse industrial machinery and equipment. Whether it's conveyor systems, agricultural machinery, or food processing equipment, these bearings can provide the necessary support and stability for smooth and efficient operation. Additionally, [Company Name] offers customization options for the bearings, allowing customers to tailor them to their specific requirements and preferences.One of the key features of the 2-bolt flange bearings is their easy installation and maintenance. The design of the bearings enables quick and hassle-free mounting, reducing downtime and labor costs for customers. Furthermore, [Company Name] provides comprehensive technical support and resources to assist customers in the proper installation and maintenance of the bearings, ensuring long-term performance and reliability.With a strong commitment to quality and customer satisfaction, [Company Name] conducts rigorous testing and quality control measures to guarantee the performance and reliability of its 2-bolt flange bearings. By adhering to international standards and regulations, [Company Name] ensures that its bearings meet the highest industry standards and specifications, providing customers with a peace of mind and confidence in their equipment.In addition to the 2-bolt flange bearings, [Company Name] offers a wide range of industrial components and solutions, including mounted bearings, roller chains, sprockets, couplings, and more. With its extensive product portfolio and engineering expertise, [Company Name] is a trusted partner for businesses across various industries, helping them achieve their operational and production goals.Furthermore, [Company Name] is dedicated to sustainability and environmental responsibility, integrating eco-friendly practices and materials into its manufacturing processes. By prioritizing sustainability, [Company Name] aims to minimize its environmental footprint and contribute to a greener and more sustainable future for the industry and the planet.As a customer-driven company, [Company Name] is committed to providing exceptional value and service to its clients. With a global presence and a strong network of distributors and partners, [Company Name] ensures prompt delivery and support for its products, regardless of the customer's location or industry.In conclusion, the introduction of the new 2-bolt flange bearings from [Company Name] reinforces its position as a leading provider of industrial components and solutions. With a focus on quality, innovation, and customer satisfaction, [Company Name] continues to be a trusted partner for businesses seeking reliable and high-performance industrial products. As the industry evolves, [Company Name] remains at the forefront, continuously developing and delivering cutting-edge solutions to meet the ever-changing needs of its customers.

Top Quality Custom Needle Bearings for Your Needs

Custom Needle Bearings (CNB) continues to be a leading provider of high-quality needle bearings, servicing a wide range of industries with precision bearing solutions. With over 30 years of experience in the industry, CNB has built a reputation for delivering exceptional products that meet the exacting requirements of their customers. This dedication to quality and customer satisfaction has solidified CNB's position as a trusted partner in the supply of custom needle bearings.CNB specializes in the design and manufacture of custom needle bearings that are tailored to meet the unique needs of each customer. The company's team of experienced engineers works closely with clients to understand their specific application requirements and design bearings that offer optimal performance and longevity. This commitment to customization sets CNB apart in the industry, allowing them to provide solutions that are truly tailored to the needs of their customers.One of the key factors that sets CNB apart is their focus on precision manufacturing. The company utilizes state-of-the-art equipment and advanced manufacturing processes to ensure that each bearing meets the highest standards of quality and consistency. This dedication to precision allows CNB to produce bearings that offer exceptional performance, even in the most demanding operating environments.In addition to their custom design capabilities, CNB also offers a comprehensive range of standard needle bearings. These bearings are available in a wide variety of sizes and configurations, making them suitable for a broad range of applications. Whether customers require standard off-the-shelf bearings or custom-designed solutions, CNB has the expertise and capabilities to meet their needs.CNB's dedication to quality extends beyond their products to their customer service and support. The company is committed to providing exceptional customer service, with a team of knowledgeable and experienced professionals ready to assist clients with their bearing needs. From initial design consultations to ongoing technical support, CNB works closely with customers to ensure that they receive the best possible solutions for their applications.Over the years, CNB has developed a strong track record of success, working with customers in a variety of industries, including automotive, aerospace, industrial machinery, and more. The company's bearings have been used in a wide range of applications, from precision instruments to heavy-duty equipment, demonstrating their versatility and reliability across various industries.Looking ahead, CNB is committed to maintaining its position as a leader in the supply of custom needle bearings. The company continues to invest in research and development to innovate new bearing solutions that meet the evolving needs of their customers. With a focus on quality, precision, and customer satisfaction, CNB remains dedicated to providing the best possible bearing solutions for their clients.In conclusion, Custom Needle Bearings (CNB) is a trusted provider of custom needle bearings, offering tailor-made solutions that meet the specific requirements of their customers. With a focus on precision manufacturing, quality, and customer service, CNB has established itself as a leader in the industry, serving a diverse range of industries with high-quality bearing solutions. As the company continues to innovate and expand its capabilities, CNB remains a reliable partner for businesses seeking exceptional custom needle bearings.

Ultimate Guide to Plummer Block Housing: Everything You Need to Know

Plummer block housings are essential components in a wide range of industrial applications, providing support and protection for rotating shafts and bearings. These housings play a critical role in ensuring the smooth and efficient operation of machinery and equipment in various industries, including mining, construction, and manufacturing.One of the leading manufacturers of high-quality plummer block housings is a company that has been at the forefront of innovation and excellence in the field of power transmission and bearing solutions for over a century. With a strong commitment to quality, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses seeking top-notch components for their operations.The company's plummer block housings are designed and engineered to meet the highest standards of performance and durability. Made from premium materials and precision-machined to exact specifications, these housings are capable of withstanding heavy loads, harsh operating conditions, and rigorous demands of industrial settings. Whether it's for a conveyor system in a mine, a heavy-duty crane at a construction site, or a production line in a manufacturing facility, the company's plummer block housings deliver the strength and resilience required to keep operations running smoothly.In addition to their robust construction, the company's plummer block housings are also designed for easy installation and maintenance. Featuring smart design elements and user-friendly interfaces, these housings help streamline the assembly process and reduce downtime for maintenance and repairs. This not only contributes to operational efficiency but also minimizes the total cost of ownership for businesses, making the company's plummer block housings a cost-effective solution for their needs.Furthermore, the company offers a comprehensive range of plummer block housings, catering to a diverse set of requirements across various industries. Whether it's standard designs or custom solutions, the company's extensive product lineup ensures that customers can find the perfect housing for their specific applications. With a focus on flexibility and adaptability, the company is well-equipped to address unique challenges and deliver tailored housing solutions that meet the exact needs of its customers.Beyond the product itself, the company is also known for its exceptional customer service and support. With a team of knowledgeable and experienced professionals, the company provides invaluable assistance to customers, helping them select the right plummer block housing for their requirements. From consultation and customization to after-sales service and technical support, the company is dedicated to ensuring a seamless and satisfying experience for its customers at every step of the way.Looking ahead, the company remains committed to driving innovation and advancing the capabilities of its plummer block housings. By staying on top of the latest technological developments and industry trends, the company continuously seeks to enhance the performance, efficiency, and reliability of its products, staying ahead of the curve and meeting the evolving needs of its customers.In conclusion, the company's plummer block housings stand as a testament to its unwavering dedication to quality, excellence, and customer satisfaction. With their exceptional performance, durability, and versatility, these housings play a vital role in supporting the operations of businesses across a wide range of industries. Backed by a legacy of leadership and a forward-looking approach, the company is poised to remain a trusted partner for businesses seeking top-tier plummer block housing solutions now and in the future.

How Rubber Shield Bearings can Protect Your Structures from Earthquake Damage

Rubber Shield Bearing Revolutionizes the Industry with Advanced Technology and Sustainable Solutions[Company Name], a leading player in the bearing industry, is making waves with their latest innovation – the rubber shield bearing. This groundbreaking product is set to revolutionize various sectors by offering enhanced performance, increased durability, and sustainable solutions.As industries continue to evolve and demand higher performance from their machinery, the need for reliable and long-lasting bearings becomes more crucial than ever. [Company Name] identifies this need and aims to cater to it by introducing the rubber shield bearing, which brings a new level of performance to the market.The rubber shield bearing is designed to provide superior functionality and long-term durability. Its innovative rubber shield provides excellent protection against contaminants such as dust, dirt, and moisture, ensuring the inner workings of machinery remain clean and safe. This feature not only extends the lifespan of the bearing but also enhances the performance of the machinery it is installed in.Furthermore, the rubber shield acts as a dampener, reducing vibrations and noise levels. This not only increases the comfort levels in various settings but also improves the overall efficiency of the machinery. Industries such as automotive, aerospace, robotics, and manufacturing will greatly benefit from this reduction in noise and vibration, as it enhances the working environment and optimizes productivity.One of the key aspects that sets the rubber shield bearing apart from its competitors is its sustainable nature. [Company Name] recognizes the growing concern for environmental impact and aims to be at the forefront of sustainable solutions. The rubber shield bearing is made from eco-friendly materials that can be recycled and reused, ensuring minimal waste and reduced carbon footprint. By incorporating sustainable practices in their production processes, [Company Name] is actively contributing to a greener and more sustainable future.The rubber shield bearing's advanced design and construction make it suitable for a wide range of applications across diverse industries. Its compatibility with various machinery and equipment allows for seamless integration, making it a versatile choice for many companies. Whether it is in heavy-duty industrial machinery or precision medical equipment, the rubber shield bearing delivers exceptional performance consistently.In addition to its technical advantages, [Company Name] aims to create customer value by offering comprehensive customer support and after-sales service. As a company with a strong focus on innovation, [Company Name] understands the importance of collaboration and actively engages in partnerships with customers. Their technical team provides guidance and assistance in selecting the most suitable bearing solution for specific requirements, ensuring optimal performance and customer satisfaction.Overall, the introduction of the rubber shield bearing by [Company Name] signifies a game-changing advancement in the bearing industry. With its unparalleled performance, sustainable nature, and compatibility across various sectors, this innovation is poised to transform the way companies approach their machinery's performance and efficiency.As industries continue to push boundaries and demand higher standards, [Company Name] remains committed to providing cutting-edge solutions that propel businesses forward. The rubber shield bearing is a testament to their dedication to innovation, sustainability, and customer satisfaction. With this new development, [Company Name] solidifies its position as a leader in the bearing industry and paves the way for a brighter, greener future.

Key Points about High-Quality Lock Systems You Should Know

Precision Lock, a leading provider of security solutions, has announced its latest line of cutting-edge locks designed to enhance the security of residential and commercial properties. With a focus on innovation and quality, Precision Lock (need remove brand name) has been at the forefront of the security industry for over 20 years, providing state-of-the-art locking mechanisms to customers worldwide.The new line of locks incorporates advanced technology and precision engineering to provide maximum security and peace of mind for homeowners and business owners alike. From high-security deadbolts to keyless entry systems, Precision Lock (need remove brand name) offers a wide range of options to suit the unique needs of each customer. The company's dedication to quality and reliability has made it a trusted name in the industry, with a reputation for delivering top-notch security solutions that stand the test of time.Precision Lock's (need remove brand name) commitment to excellence is evident in its state-of-the-art manufacturing facilities and rigorous quality control processes. Each lock is meticulously crafted using the latest manufacturing techniques and materials, ensuring that it meets the highest standards of durability and reliability. With a focus on innovation, Precision Lock (need remove brand name) continues to push the boundaries of what is possible in the world of security, constantly seeking out new technologies and design concepts to stay ahead of the curve.In addition to its dedication to quality, Precision Lock (need remove brand name) is also committed to sustainability and environmental responsibility. The company has implemented eco-friendly manufacturing processes and materials, ensuring that its products have minimal impact on the environment. By prioritizing sustainability, Precision Lock (need remove brand name) is not only providing top-of-the-line security solutions but also contributing to a greener, more sustainable future for generations to come.The company's new line of locks has already generated significant interest from customers and industry professionals alike. With its sleek design and advanced security features, the locks are a testament to Precision Lock's (need remove brand name) ongoing commitment to excellence and innovation. The company's dedication to staying ahead of the curve in terms of technology and design has positioned it as a leading force in the security industry, setting the standard for what customers can expect from a high-quality lock manufacturer."We are thrilled to introduce our latest line of locks, which represent the culmination of years of research, development, and innovation," said [spokesperson's name], the CEO of Precision Lock (need remove brand name). "We believe that security should be reliable, easy to use, and provide peace of mind for our customers. We are confident that our new line of locks embodies these principles and sets a new standard for security solutions in the industry."As the security landscape continues to evolve, Precision Lock (need remove brand name) remains committed to providing cutting-edge solutions that address the ever-changing needs of its customers. By staying at the forefront of technological advancements and design trends, the company is well-positioned to continue leading the way in the security industry for years to come. With a proven track record of excellence and a dedication to customer satisfaction, Precision Lock (need remove brand name) is a name that customers can trust when it comes to protecting their homes and businesses.

Discover the Latest Gears and Bearings Technology

Gears Bearing, a leading provider of high-quality precision bearings and other mechanical parts, has recently announced the launch of several new products designed to meet the needs of the ever-evolving industrial market. With over 20 years of experience in the industry, Gears Bearing has established a strong reputation for delivering reliable and efficient solutions to customers worldwide.The company’s extensive product range includes a variety of bearings such as ball bearings, roller bearings, and thrust bearings, as well as gears, sprockets, and other power transmission components. These products are widely used in industries such as automotive, aerospace, mining, construction, and renewable energy, among others.In a statement released by the company, Gears Bearing emphasized its commitment to innovation and continuous improvement. “We are dedicated to providing our customers with the highest quality products that meet their specific requirements,” said a spokesperson for the company. “Our team of engineers and technical experts work tirelessly to develop new and improved solutions that help our customers stay ahead in their respective industries.”One of the key highlights of Gears Bearing’s new product range is the introduction of advanced bearing materials and coatings that offer enhanced durability and performance. These innovative materials and coatings are specially designed to withstand extreme operating conditions, including high temperatures, heavy loads, and corrosive environments. By incorporating these advancements into their products, Gears Bearing aims to prolong the lifespan of machinery and equipment, ultimately reducing maintenance costs for its customers.Furthermore, Gears Bearing has also expanded its range of custom-engineered solutions to address the unique challenges faced by different industries. The company’s team of engineers works closely with customers to understand their specific requirements and develop tailored solutions that optimize the performance of their machinery and equipment.In addition to its product innovations, Gears Bearing places a strong emphasis on quality and reliability. The company adheres to strict quality control measures throughout the manufacturing process to ensure that every product meets the highest standards of excellence. Furthermore, Gears Bearing is certified to ISO 9001, demonstrating its commitment to upholding quality management practices and delivering superior products to its customers.Gears Bearing is also known for its exceptional customer service and technical support. The company’s team of sales and customer service representatives are readily available to provide expert guidance and assistance to customers, helping them select the right products for their specific applications. Additionally, Gears Bearing offers comprehensive technical documentation and resources to support its customers in the installation, operation, and maintenance of its products.As Gears Bearing continues to expand its product offerings and strengthen its position in the market, the company reaffirms its dedication to driving innovation and delivering value to its customers. With a focus on quality, reliability, and customer satisfaction, Gears Bearing remains a trusted partner for businesses seeking high-performance solutions for their mechanical and industrial needs.In conclusion, Gears Bearing’s latest product launch and commitment to innovation underscore the company’s position as a leading provider of precision bearings and mechanical components. With a focus on quality, reliability, and customer satisfaction, Gears Bearing is well-equipped to meet the evolving needs of the industrial market and support businesses in achieving their operational goals.

Rubber Sealed Bearings: What You Need to Know

Bearing With Rubber Seal: The Perfect Solution for Industrial ApplicationsIn industrial applications, where heavy machinery and equipment are used, the use of high-quality bearings is crucial. Bearings play a crucial role in ensuring smooth and efficient operation of the machinery. One of the key factors that determine the performance and longevity of bearings is the presence of effective seals. This is where the Bearing With Rubber Seal, developed by [Company Name], proves to be the perfect solution for industrial applications.[Company Name] has been a leading manufacturer of bearings and related products for several years. With a strong focus on quality and innovation, the company has built a reputation for delivering reliable and high-performing products. The Bearing With Rubber Seal is a testament to [Company Name]'s commitment to excellence and its ability to develop cutting-edge solutions for the industrial sector.The Bearing With Rubber Seal is designed to provide superior protection against contaminants such as dust, dirt, and moisture. The rubber seal effectively seals the bearing, preventing the ingress of harmful particles and ensuring smooth operation even in harsh industrial environments. This is particularly important in applications where the machinery is exposed to extreme conditions, such as high temperatures, heavy loads, and high speeds.One of the key advantages of the Bearing With Rubber Seal is its ability to extend the service life of the bearing. By preventing the entry of contaminants, the rubber seal helps to minimize wear and tear, thereby reducing the frequency of maintenance and replacement. This not only leads to cost savings but also improves the overall efficiency and productivity of the machinery.In addition to superior sealing performance, the Bearing With Rubber Seal also offers low friction and reduced energy consumption. The design of the seal minimizes friction between the seal and the bearing, ensuring smooth rotation and minimal power loss. This is crucial for applications where energy efficiency is a priority, such as in heavy machinery and equipment used in the manufacturing and construction sectors.The Bearing With Rubber Seal is available in a wide range of sizes and configurations to meet the diverse needs of industrial applications. Whether it's for heavy-duty conveyors, mining equipment, agricultural machinery, or automotive systems, [Company Name] offers a comprehensive range of bearings with rubber seals to suit various requirements. Moreover, the company also provides custom solutions to meet specific application needs, demonstrating its flexibility and dedication to customer satisfaction.Furthermore, [Company Name] prides itself on its strict quality control and testing procedures to ensure the reliability and performance of its products. The Bearing With Rubber Seal undergoes rigorous testing to meet industry standards and customer expectations. This commitment to quality assurance has earned [Company Name] the trust and loyalty of customers worldwide.In conclusion, the Bearing With Rubber Seal from [Company Name] is a game-changer for industrial applications. With its superior sealing performance, extended service life, low friction, and energy efficiency, this product sets a new standard for bearings in demanding industrial environments. With a strong track record of quality and innovation, [Company Name] continues to lead the way in delivering solutions that drive the success of the industrial sector. For businesses looking to optimize the performance and reliability of their machinery, the Bearing With Rubber Seal is the ideal choice.

Advanced Medical Bearings Offer Enhanced Performance for Medical Devices" could be rewritten as "Innovative Bearings for Medical Devices Improve Functionality.

[Company Name] Introduces Advanced Medical Device Bearings Revolutionizing Healthcare[City, State], [Date] - [Company Name], a leading provider of innovative solutions in the healthcare industry, has recently unveiled its latest breakthrough in medical device technology - a cutting-edge medical device bearing that is set to revolutionize the healthcare sector. The company's revolutionary product aims to enhance the performance and longevity of medical devices, paving the way for improved patient care and increased efficiency within healthcare facilities worldwide.Medical devices play a crucial role in modern healthcare, aiding in the diagnosis, treatment, and monitoring of various conditions. From pacemakers to surgical instruments, these devices require components that can withstand rigorous use and deliver precise performance. One critical component is the bearing, which allows for smooth and frictionless movement within these devices.[Company Name]'s new medical device bearing offers a range of key features that set it apart from conventional bearings currently on the market. It leverages advanced materials and groundbreaking engineering techniques to provide optimal performance, reliability, and durability. The bearings are designed with utmost precision to ensure minimal friction, allowing for smoother operation and more efficient energy transmission within medical devices.One of the notable features of the [Company Name]'s medical device bearings is their compact size, which enables them to fit seamlessly into various medical device applications. This compactness not only enhances the portability of medical devices but also ensures patients' comfort during procedures. Additionally, the bearings are engineered to be lightweight, reducing the overall weight of medical devices and increasing the ease of use for healthcare professionals.Furthermore, the bearings are designed to resist wear and tear even under the most demanding circumstances. With a special focus on longevity, [Company Name] has incorporated advanced materials that exhibit excellent resistance to corrosion, high temperatures, and harsh chemicals commonly encountered in medical environments. This durability ensures that medical devices equipped with these bearings can withstand repeated sterilization processes and maintain their performance over an extended lifespan, minimizing the need for frequent replacements.Patient safety and comfort are at the forefront of [Company Name]'s product development. The medical device bearings undergo rigorous testing to comply with stringent industry standards and regulations. The company's commitment to quality assurance ensures that the bearings are reliable and safe for use in critical healthcare applications.The introduction of [Company Name]'s advanced medical device bearings is expected to have a significant impact on the healthcare industry. By improving the performance and longevity of medical devices, healthcare professionals can provide more precise and effective treatments for patients. Increased durability means fewer device failures, leading to reduced downtime and cost savings for healthcare facilities. Furthermore, the compact size and lightweight nature of these bearings allow for greater mobility and flexibility in medical procedures, improving overall patient care.[Company Name]'s dedication to innovation and cutting-edge technology has positioned them as a leading provider of medical device solutions. With their latest breakthrough in medical device bearings, they continue to push the boundaries of what is possible in the healthcare industry. The company's commitment to improving patient outcomes and revolutionizing healthcare sets them apart as an industry leader, ready to shape the future of medical device technology.About [Company Name]:[Company Name] is a renowned provider of innovative solutions in the healthcare industry. With a focus on cutting-edge technology and exceptional quality, the company is committed to improving patient care while driving efficiency within healthcare facilities. Through its advanced medical device solutions, [Company Name] has established itself as a trusted partner for healthcare professionals worldwide.