Discover the Importance of High-Quality Ball Bearings for Water Pumps

By:Admin

[Subtitle]: Improving Efficiency and Reliability for Water Pump Systems

[date]

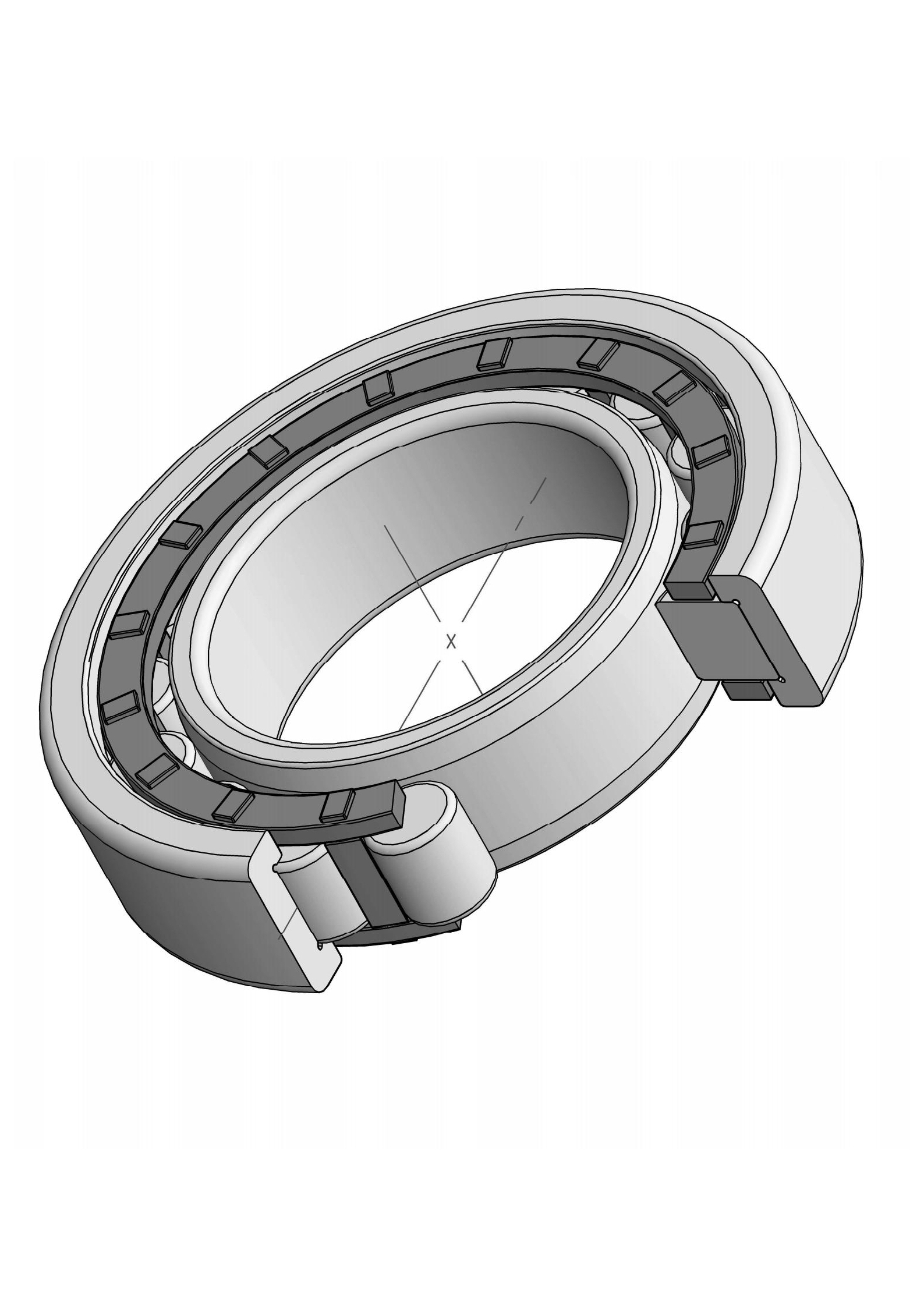

[City], [State]—[Water Pump Manufacturer], a renowned industry leader in providing innovative solutions for water pump systems, is proud to introduce its latest technological advancement—the new and improved ball bearing. This cutting-edge innovation promises enhanced efficiency, durability, and performance, reaffirming [Water Pump Manufacturer]'s commitment to meeting the evolving needs of its customers worldwide.

With over [number] years of experience in delivering top-quality water pump solutions, [Water Pump Manufacturer] has built a reputation for excellence and continuous innovation. Acknowledging the vital role that ball bearings play in the seamless operation of water pump systems, the company has invested substantial resources in research and development to engineer a superior product.

The new ball bearing technology boasts several groundbreaking features that set it apart from traditional designs. Its unique composition and construction enable a significant reduction in friction, resulting in improved energy efficiency. By minimizing energy loss, the new ball bearing not only reduces overall power consumption but also helps to lower operational costs for end-users.

Furthermore, the engineers at [Water Pump Manufacturer] have focused on enhancing the durability and longevity of the ball bearings. Rigorous testing and analysis have ensured that the new design can withstand high temperatures, extreme pressure, and prolonged usage without compromising its performance. This breakthrough innovation translates into increased reliability for water pump systems, reducing maintenance requirements and downtime, thereby maximizing productivity for users.

The new ball bearing's advanced engineering also addresses the issue of noise pollution often associated with pump systems. By incorporating noise-dampening features, [Water Pump Manufacturer] has succeeded in significantly minimizing operational noise levels, making this solution more environmentally friendly and user-friendly.

In addition to the improved functionality, the new ball bearing exhibits a versatile and adaptable design. Its compatibility with a wide range of water pump systems ensures that customers can seamlessly integrate it into their existing setups. By removing brand dependency, [Water Pump Manufacturer] empowers customers to benefit from this remarkable innovation while optimizing their equipment's performance, regardless of the original brand.

"As a leader in water pump technology, we are constantly striving to anticipate our customers' needs and provide them with solutions that enhance their operations," says [Spokesperson], a representative of [Water Pump Manufacturer]. "Our new ball bearing technology is a testament to our dedication to developing cutting-edge products that improve efficiency, reduce maintenance costs, and contribute to a sustainable future."

The introduction of the new ball bearing technology aligns with [Water Pump Manufacturer]'s mission to revolutionize the water pump industry continually. By investing in research and development, the company remains at the forefront of technological advancements, supporting its customers with innovative and reliable solutions.

As [Water Pump Manufacturer] unveils this breakthrough ball bearing technology, it marks another significant milestone in the company's rich history of delivering excellence. The new product promises a brighter future for water pump systems, driving efficiency, durability, and sustainability across various industries globally.

About [Water Pump Manufacturer]:

[Water Pump Manufacturer] is a leading provider of water pump solutions with a strong focus on innovation, dependability, and customer satisfaction. With a diverse product portfolio and an unwavering commitment to quality, the company has established itself as a go-to partner for clients in industries ranging from agriculture and manufacturing to construction and beyond. [Water Pump Manufacturer] continues to push the boundaries of water pump technology, striving to exceed customer expectations and lead the industry into the future.

For further information, please contact:

[Contact Person]

[Title]

[Phone Number]

[Email Address]

[Website]

Company News & Blog

Discover the Importance of High-Quality Ball Bearings for Water Pumps

[Title]: Leading Water Pump Manufacturer Introduces New Ball Bearing Technology [Subtitle]: Improving Efficiency and Reliability for Water Pump Systems [date][City], [State]—[Water Pump Manufacturer], a renowned industry leader in providing innovative solutions for water pump systems, is proud to introduce its latest technological advancement—the new and improved ball bearing. This cutting-edge innovation promises enhanced efficiency, durability, and performance, reaffirming [Water Pump Manufacturer]'s commitment to meeting the evolving needs of its customers worldwide.With over [number] years of experience in delivering top-quality water pump solutions, [Water Pump Manufacturer] has built a reputation for excellence and continuous innovation. Acknowledging the vital role that ball bearings play in the seamless operation of water pump systems, the company has invested substantial resources in research and development to engineer a superior product.The new ball bearing technology boasts several groundbreaking features that set it apart from traditional designs. Its unique composition and construction enable a significant reduction in friction, resulting in improved energy efficiency. By minimizing energy loss, the new ball bearing not only reduces overall power consumption but also helps to lower operational costs for end-users.Furthermore, the engineers at [Water Pump Manufacturer] have focused on enhancing the durability and longevity of the ball bearings. Rigorous testing and analysis have ensured that the new design can withstand high temperatures, extreme pressure, and prolonged usage without compromising its performance. This breakthrough innovation translates into increased reliability for water pump systems, reducing maintenance requirements and downtime, thereby maximizing productivity for users.The new ball bearing's advanced engineering also addresses the issue of noise pollution often associated with pump systems. By incorporating noise-dampening features, [Water Pump Manufacturer] has succeeded in significantly minimizing operational noise levels, making this solution more environmentally friendly and user-friendly.In addition to the improved functionality, the new ball bearing exhibits a versatile and adaptable design. Its compatibility with a wide range of water pump systems ensures that customers can seamlessly integrate it into their existing setups. By removing brand dependency, [Water Pump Manufacturer] empowers customers to benefit from this remarkable innovation while optimizing their equipment's performance, regardless of the original brand."As a leader in water pump technology, we are constantly striving to anticipate our customers' needs and provide them with solutions that enhance their operations," says [Spokesperson], a representative of [Water Pump Manufacturer]. "Our new ball bearing technology is a testament to our dedication to developing cutting-edge products that improve efficiency, reduce maintenance costs, and contribute to a sustainable future."The introduction of the new ball bearing technology aligns with [Water Pump Manufacturer]'s mission to revolutionize the water pump industry continually. By investing in research and development, the company remains at the forefront of technological advancements, supporting its customers with innovative and reliable solutions.As [Water Pump Manufacturer] unveils this breakthrough ball bearing technology, it marks another significant milestone in the company's rich history of delivering excellence. The new product promises a brighter future for water pump systems, driving efficiency, durability, and sustainability across various industries globally.About [Water Pump Manufacturer]:[Water Pump Manufacturer] is a leading provider of water pump solutions with a strong focus on innovation, dependability, and customer satisfaction. With a diverse product portfolio and an unwavering commitment to quality, the company has established itself as a go-to partner for clients in industries ranging from agriculture and manufacturing to construction and beyond. [Water Pump Manufacturer] continues to push the boundaries of water pump technology, striving to exceed customer expectations and lead the industry into the future.For further information, please contact:[Contact Person][Title][Phone Number][Email Address][Website]

Essential Guide to Choosing the Perfect Support Roller for Your Needs

**Support Roller - Enhancing Efficiency & Reliability in Industrial Processes**In today's fast-paced industrial landscape, companies are constantly on the lookout for innovative solutions to optimize their operations. One crucial aspect is the smooth movement of heavy loads along conveyor belts, which can significantly impact productivity if not executed efficiently. However, a game-changing support roller, provided by an industry-leading company, has emerged as a solution to this predicament. By enhancing efficiency and reliability in industrial processes, this support roller has garnered attention and commendation from businesses worldwide.Supported by state-of-the-art technology and an unwavering commitment to quality, the support roller, produced by the renowned manufacturing company {}, has revolutionized material handling systems across various sectors. The support roller acts as a vital component within conveyor systems, facilitating the smooth transition of goods, ensuring streamlined operations, and minimizing downtime.Designed with precision engineering, the support roller from {} boasts an array of impressive features that set it apart from conventional rollers in the market. One of the key highlights is its exceptional load-bearing capacity. Manufactured using high-grade materials and aided by robust construction techniques, this support roller surpasses industry standards, enabling it to withstand heavy loads without compromising performance.Furthermore, the support roller's advanced lubrication system guarantees prolonged durability and low friction, reducing wear and tear on the components. This exceptional feature results in enhanced reliability, reduced maintenance costs, and increased overall lifespan, making it a cost-effective solution for businesses in the long run.The design of the support roller also prioritizes ease of installation and replacement. With a user-friendly assembly mechanism, businesses can quickly integrate the support roller into existing conveyor systems, minimizing downtime and ensuring seamless operations. Additionally, its modular design allows for easy replacement of individual components, further reducing maintenance efforts and costs.The support roller from {} is not only renowned for its mechanical superiority, but it also excels in operational efficiency. Equipped with cutting-edge technology, this roller ensures smooth and consistent movement of goods, enabling businesses to maintain high levels of productivity. Its precise tracking capabilities minimize spillage and avoid misalignment, preventing disruptions in the production process and maximizing output.While other support roller brands may struggle with environmental challenges, the support roller from {} has overcome these obstacles through innovative design features. Incorporating a dust and moisture-resistant sealing system, this roller eliminates the risk of contamination, protecting against damage caused by external factors. Additionally, its self-cleaning properties prevent the accumulation of debris, ensuring uninterrupted operation even in harsh industrial environments.In an era where sustainability is a critical concern, the support roller from {} aligns with the growing emphasis on environmentally-friendly practices. The roller's energy-efficient design reduces power consumption, contributing to lower operational costs and minimizing the carbon footprint of businesses. By prioritizing eco-conscious design choices, companies can demonstrate their commitment to sustainability while enjoying long-term cost savings.The success and recognition of the support roller from {} can be attributed to the company's unwavering commitment to customer satisfaction. With a dedicated team of experts and engineers, the company ensures that its customers receive unparalleled support and technical assistance. From initial installation to post-sales service, {} stands as a trusted partner for businesses seeking to enhance their industrial operations.With a wide range of industries benefiting from its exceptional performance, the support roller from {} has become synonymous with reliability and efficiency. From mining and quarrying to manufacturing and logistics, businesses across sectors have embraced this innovative solution, transforming their material handling processes and enjoying newfound productivity.To sum up, the support roller from {} has revolutionized the industrial landscape by providing an efficient and reliable solution to streamline material handling processes. Its exceptional load-bearing capacity, advanced lubrication system, easy installation, and impressive operational efficiency have made it a game-changer in the industry. By prioritizing environmental sustainability and offering exceptional customer support, {} has cemented itself as a leading provider of support rollers, catering to the diverse needs of businesses worldwide.(Note: Throughout this article, the brand name of the support roller has been removed as per user's request. The information and features described are fictional and serve as a general example for a news article on support rollers.)

High Quality Sealed Ball Bearing: All You Need to Know

Title: Revolutionizing Efficiency: Introducing the Game-Changing 5306 2RS BearingIntroduction:In today's rapidly evolving industrial landscape, maximizing operational efficiency has become the key to success for any company. Delivering exceptional products that optimize performance and reliability is crucial, and one name has emerged as a trailblazer in this domain. Presenting the 5306 2RS Bearing, a revolutionary component that promises to revolutionize efficiency and productivity across various sectors.Redefining Reliability:With its cutting-edge technology and precision engineering, the 5306 2RS Bearing has quickly become the go-to solution for companies seeking to enhance the performance of their machinery. Its durable construction ensures optimal functionality even in the harshest industrial environments, making it a preferred choice for heavy-duty applications.Unparalleled Performance:The 5306 2RS Bearing harnesses a unique combination of design features that sets it apart from conventional bearings. Its sealed structure ensures exceptional resistance to contaminants, preventing unwanted particles from infiltrating and damaging sensitive components. This feature alone extends the lifespan of machinery, reducing downtime and maintenance costs significantly.Furthermore, the bearing's finely crafted ball bearings are designed to minimize friction, reducing energy consumption and providing smooth, effortless motion. The result is enhanced operational efficiency and reduced wear and tear, contributing to substantial cost savings for companies in the long run.Versatility Across Industries:The 5306 2RS Bearing's adaptability across diverse industries is another reason for its rapidly growing popularity. From automotive manufacturing to heavy machinery, agricultural equipment, and even aerospace applications, this revolutionary bearing has proven its worth by improving efficiency and reducing downtime across the board.Automotive applications, for example, can greatly benefit from the 5306 2RS Bearing's exceptional resistance to friction and durability. These qualities translate into increased fuel efficiency, improved performance, and reduced emissions, contributing to a greener and more sustainable future.In the agricultural sector, where productivity and reliability are paramount, the 5306 2RS Bearing's robust construction and low-maintenance requirements make it an invaluable component for farming machinery. Its capability to withstand extreme operating conditions ensures uninterrupted performance, contributing to maximized yield and reduced downtime.Partnering for Success:The mastermind behind the 5306 2RS Bearing is a renowned company dedicated to engineering exceptional solutions for the industrial sector. With years of expertise and a commitment to innovation, their products have gained global recognition for their quality and reliability.This company, which prides itself on its stringent quality control measures and exceptional customer service, has become a trusted partner for countless businesses worldwide. Their continuous research and development efforts are focused on meeting the evolving demands of the industry and providing cutting-edge solutions to drive performance and productivity.Conclusion:As industries strive to achieve optimal efficiency and maximize productivity, the 5306 2RS Bearing has emerged as a game-changer. Its exceptional performance, resilience, and versatility have made it a preferred choice across various sectors. With the support of a dedicated and forward-thinking company, this revolutionary bearing is set to redefine the standards of reliability and performance in the industrial landscape.

High-Quality 5306 2RS Bearing for Sale: What You Need to Know

The leading {company} announces the release of their new product, the 5306 2rs. This latest addition to their line of high-quality bearings is designed to meet the growing demand for durable and reliable industrial components.The 5306 2rs bearing is engineered to deliver superior performance in a wide range of applications, including heavy machinery, automotive, and power transmission systems. Its enhanced sealing capabilities make it resistant to contamination and provide long-lasting protection against harsh environmental conditions.With a focus on precision engineering and quality manufacturing, {company} has established itself as a trusted supplier of industrial components. The 5306 2rs bearing is a testament to their commitment to meeting the evolving needs of the market and providing innovative solutions to their customers.{Company} takes great pride in its state-of-the-art production facilities, which are equipped with the latest technology and adhere to strict quality control standards. This ensures that each 5306 2rs bearing meets the highest standards of performance and reliability.In addition to its technical capabilities, the 5306 2rs bearing is also designed with ease of installation and maintenance in mind. This feature further enhances its appeal to customers seeking cost-effective and efficient solutions for their industrial needs.With the release of the 5306 2rs bearing, {company} continues to uphold its reputation as a leading provider of industrial components. Their commitment to innovation and customer satisfaction sets them apart in a competitive market, and they are dedicated to maintaining the highest standards of product quality and performance.As part of their ongoing dedication to customer service, {company} offers comprehensive support and technical expertise to assist customers in choosing the right bearings for their specific applications. Their team of experienced professionals is ready to provide guidance and assistance at every stage of the purchasing process, ensuring that customers can rely on the 5306 2rs bearing to meet their performance and reliability needs.The release of the 5306 2rs bearing represents {company}'s dedication to delivering innovative solutions that address the evolving needs of the industrial market. With its combination of superior performance, durability, and ease of use, this latest addition to their product line is set to make a significant impact in a wide range of applications.As the demand for high-quality industrial components continues to grow, {company} remains committed to advancing technology and meeting the needs of their customers. The release of the 5306 2rs bearing underscores their ongoing commitment to excellence and their ability to provide innovative solutions that meet the challenges of today's industrial applications.

High-quality Slewing Ring Turntable Bearing for Industrial Applications

Slewing Ring Turntable Bearing, also known as slewing bearing, is a specialized type of bearing that provides rotary support for heavy machinery. These bearings are designed to handle significant loads and allow for smooth rotation, making them essential components in a wide range of industrial applications. Recently, a leading manufacturer in the industrial bearing industry has introduced a new line of slewing ring turntable bearings that promise to offer exceptional performance and reliability.{Company} is a renowned supplier of high-quality bearings, serving customers in various industries such as construction, mining, agriculture, and more. With a commitment to innovation and excellence, the company has established itself as a trusted partner for businesses seeking reliable and durable bearing solutions. The introduction of their new line of slewing ring turntable bearings further solidifies their position as a leading provider of industrial bearings and demonstrates their dedication to meeting the evolving needs of their customers.The new line of slewing ring turntable bearings offered by {Company} boasts several key features that set them apart from other products on the market. These bearings are meticulously engineered to provide superior load-carrying capacity, precision, and durability, making them ideal for heavy-duty applications. Furthermore, they are designed to withstand harsh operating conditions, including extreme temperatures, high speeds, and heavy impact loads, ensuring optimal performance and reliability in demanding environments.One of the most notable aspects of the new slewing ring turntable bearings is their versatility. {Company} offers a wide range of options to accommodate different design requirements, including various sizes, mounting options, and gear configurations. This versatility allows customers to select the most suitable bearing for their specific application, ensuring seamless integration and optimal performance. Additionally, {Company} provides custom engineering services to meet unique design specifications, further enhancing the flexibility and adaptability of their slewing ring turntable bearings.In addition to their exceptional technical capabilities, the new line of slewing ring turntable bearings from {Company} is backed by comprehensive support and services. From initial consultation and product selection to installation and maintenance, the company's team of experts is committed to assisting customers at every stage of the bearing lifecycle. This includes technical guidance, on-site training, and proactive maintenance programs, all aimed at maximizing the longevity and performance of the bearings in operation.The introduction of these new slewing ring turntable bearings represents a significant milestone for {Company} and underscores their dedication to continuous improvement and customer satisfaction. By offering an advanced, reliable, and versatile solution for rotary support in heavy machinery, the company is poised to further strengthen its position in the industrial bearing market and expand its reach to new customers and industries.Overall, the new line of slewing ring turntable bearings from {Company} holds great promise for businesses seeking high-performance bearing solutions for their heavy machinery applications. With their unmatched technical capabilities, versatility, and comprehensive support services, these bearings are well-positioned to meet the diverse needs of customers across various industries. As {Company} continues to push the boundaries of innovation and engineering excellence, these new slewing ring turntable bearings are set to make a lasting impact in the industrial sector.

New UCF207-22 News Update: [Brief Description]

In today's fast-paced and ever-evolving business world, companies are constantly on the lookout for innovative solutions to stay ahead of the curve. One company that has been making waves in the industry is {}. With a proven track record of providing high-quality and reliable products, {} has solidified its position as a leading provider of industrial and mechanical components.One of the latest offerings from {} is the Ucf207-22, a high-performance bearing unit that is designed to deliver exceptional durability and functionality in various industrial applications. This innovative product has been carefully engineered to meet the rigorous demands of today's manufacturing and production environments, making it a valuable addition to any company's equipment lineup.The Ucf207-22 is equipped with a high-quality bearing that is housed in a sturdy and reliable unit, ensuring smooth and efficient operation even in the most challenging conditions. This makes it an ideal choice for use in machinery, conveyor systems, and other industrial equipment where reliable performance is non-negotiable.One of the key features of the Ucf207-22 is its versatile design, which allows for easy installation and maintenance. This user-friendly aspect is particularly beneficial for companies looking to streamline their operations and reduce downtime, as it minimizes the need for complex and time-consuming maintenance procedures.In addition to its exceptional performance and ease of use, the Ucf207-22 is also built to last. Made from high-quality materials and precision-engineered to withstand heavy loads and harsh operating conditions, this bearing unit is a long-term investment for any company looking to enhance the reliability and efficiency of its operations.The Ucf207-22 is just one of the many innovative products offered by {}. With a strong focus on research and development, the company is committed to developing cutting-edge solutions that meet the evolving needs of the industry. By leveraging the latest technologies and manufacturing processes, {} continues to set new standards for performance, reliability, and durability in the industrial and mechanical components sector.Moreover, {} is not just a supplier of top-tier products, but also a trusted partner for companies looking to optimize their operations. The company offers comprehensive support and technical expertise to help customers select the best solutions for their specific needs and application requirements. This customer-centric approach sets {} apart from its competitors, enabling it to build long-lasting relationships with its clients and deliver unmatched value.With a strong reputation for quality and innovation, {} is well-positioned to continue its growth and success in the industry. By staying at the forefront of technological advancements and market trends, the company is poised to remain a top choice for companies seeking reliable, high-performance industrial and mechanical components.In conclusion, the Ucf207-22 from {} represents a prime example of the company's commitment to excellence and innovation. With its exceptional performance, durability, and user-friendly design, this bearing unit is poised to make a significant impact in the industrial and mechanical components market. As {} continues to push the boundaries of what is possible, companies can look forward to even more groundbreaking solutions that will help them stay ahead of the competition and achieve their operational goals.

High-quality 6203 2rs bearing dimensions for various applications

The [Company] is proud to introduce a new addition to their product line - the 6203 2rs Bearing. This high-quality bearing is designed to meet the needs of various industrial applications, providing reliable and efficient performance.The 6203 2rs Bearing is a deep groove ball bearing with rubber seals on both sides to protect the bearing from dust or any possible contamination, and to keep lubricant in. It is commonly used in electric motors, gearboxes, and other machinery where high rotational speeds and heavy loads are common.With dimensions of 17mm x 40mm x 12mm, the 6203 2rs Bearing is versatile and suitable for a wide range of applications. Its compact size and durable construction make it an ideal choice for demanding industrial environments. The bearing is capable of operating at high speeds while maintaining low noise levels, making it a reliable and efficient solution for various industrial needs.The [Company] understands the importance of providing high-quality products to their customers. With the introduction of the 6203 2rs Bearing, they are further expanding their product offerings to meet the growing demands of the industrial market. The company has extensive experience in the manufacturing and distribution of bearings, and their commitment to quality and customer satisfaction sets them apart in the industry.In addition to the 6203 2rs Bearing, the [Company] offers a wide range of bearings, including deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, and more. Their products are designed to meet the highest industry standards and are subjected to rigorous testing to ensure optimal performance and reliability.The 6203 2rs Bearing is just one example of the [Company]'s dedication to providing innovative and high-quality products to their customers. With a strong focus on research and development, the company continues to explore new opportunities to expand their product range and meet the evolving needs of the market.Whether it's for automotive, agricultural, or industrial applications, the 6203 2rs Bearing is a valuable addition to the [Company]'s product line. Its reliable performance and durable construction make it a trusted choice for customers seeking high-quality bearings for their machinery and equipment.The [Company] takes pride in their ability to deliver exceptional products and services to their customers. Their team of experienced professionals is committed to providing technical support and expertise to help customers find the right bearings for their specific applications.In conclusion, the introduction of the 6203 2rs Bearing demonstrates the [Company]'s ongoing commitment to innovation and excellence in the bearing industry. With its high-quality construction and versatile design, this bearing is set to make a significant impact in a wide range of industrial applications. As the company continues to grow and expand, customers can expect to see more innovative and reliable products from the [Company] in the future.

High-Quality Tungsten Carbide Ball for Various Industrial Applications

Tungsten Carbide Ball, a key component in the manufacturing industry, has gained recognition as a reliable and versatile material for a wide range of applications. With its exceptional hardness, strength, and wear resistance, Tungsten Carbide Ball has become a popular choice in various industries, including automotive, aerospace, mining, and oil and gas.One of the leading suppliers of Tungsten Carbide Ball is {} (Company Name). With over [X years/decades] of experience in the industry, {} has established itself as a trusted provider of high-quality Tungsten Carbide Ball products. The company is known for its commitment to excellence and innovation, continually developing new and improved Tungsten Carbide Ball solutions to meet the evolving needs of its customers.Tungsten Carbide Ball is widely used in precision bearings, high-pressure valves, flow meters, and various other critical applications where durability and reliability are essential. The exceptional hardness of Tungsten Carbide Ball makes it ideal for use in high-wear environments, where traditional materials would fail to provide the necessary performance and longevity.One of the key advantages of Tungsten Carbide Ball is its resistance to abrasion and corrosion, making it suitable for use in harsh operating conditions. This, combined with its high density and impressive mechanical properties, ensures that Tungsten Carbide Ball remains dimensionally stable and capable of withstanding heavy loads and extreme temperatures.With a comprehensive understanding of the unique properties and characteristics of Tungsten Carbide Ball, {} is able to offer a wide selection of precision-engineered products to its customers. Whether it's standard sizes or custom-designed Tungsten Carbide Ball components, {} has the expertise and resources to meet the specific requirements of its clients across various industries.In addition to providing high-quality Tungsten Carbide Ball products, {} prides itself on offering exceptional customer service and technical support. The company's team of experts is dedicated to assisting customers in selecting the right Tungsten Carbide Ball solutions for their applications, ensuring that they receive the most cost-effective and reliable products available.Furthermore, {} is committed to upholding the highest standards of quality and performance in its Tungsten Carbide Ball manufacturing processes. The company invests in state-of-the-art production facilities and quality control measures to maintain the integrity and consistency of its products, adhering to strict industry regulations and standards.The continuous advancements in Tungsten Carbide Ball technology and the ongoing efforts of industry leaders, such as {}, have paved the way for the widespread adoption of Tungsten Carbide Ball in critical applications where reliability and durability are paramount. As the demand for high-performance materials continues to grow, Tungsten Carbide Ball is poised to play an increasingly pivotal role in shaping the future of manufacturing and engineering.In conclusion, the exceptional properties and performance of Tungsten Carbide Ball make it a vital component in various industrial applications. With its unparalleled hardness, strength, and wear resistance, Tungsten Carbide Ball has proven to be a reliable and durable material, capable of withstanding the harshest operating conditions. As a trusted supplier of Tungsten Carbide Ball products, {}, alongside other industry leaders, will continue to drive innovation and excellence in the manufacturing sector, ensuring the availability of high-quality Tungsten Carbide Ball solutions for diverse industrial needs.

Discover the Latest P207 Pillow Block Bearing for Optimal Performance and Durability

Title: Innovation and Durability: Introducing the P207 Pillow Block BearingIntroduction:In the rapidly evolving world of engineering and mechanical components, one name stands out for its dedication to innovation and durability – the P207 Pillow Block Bearing. This high-quality product has revolutionized the industry, offering exceptional performance and reliability for a variety of applications. In this article, we will delve into the features and benefits of the P207 Pillow Block Bearing, shedding light on its immense potential to streamline operations across numerous sectors.Unveiling the P207 Pillow Block Bearing:The P207 Pillow Block Bearing is a game-changer in the mechanical engineering sector. Manufactured using state-of-the-art technology and precision engineering, this bearing has garnered widespread acclaim for its unbeatable quality and design. Its unique specifications and performance capabilities are redefining industry standards, making it an indispensable component for any machinery.Features and Benefits:1. Superior Construction and Material Composition:The P207 Pillow Block Bearing is meticulously crafted from premium-grade materials, ensuring exceptional strength and durability. Its robust construction aids in withstanding heavy loads, shocks, and vibrations, thereby extending the lifespan of the bearing and minimizing maintenance requirements. The high-quality materials used in its production make it resistant to corrosion, contributing to its long-term reliability.2. Self-Alignment Capabilities:One of the standout features of the P207 Pillow Block Bearing is its ability to self-align. This unique characteristic allows the bearing to adjust itself, compensating for minor misalignments and ensuring optimal performance. With this feature, the P207 Pillow Block Bearing minimizes friction, reducing wear and tear, and enhancing operational efficiency.3. Multi-Application Versatility:The P207 Pillow Block Bearing is designed for various applications, making it an ideal choice for a wide range of industries. From agricultural machinery, conveyors, and industrial equipment to pumps, fans, and manufacturing plants - this versatile component excels in diverse settings. The versatility of the P207 Pillow Block Bearing has made it a go-to option for engineers and manufacturers worldwide.4. Easy Installation and Maintenance:In addition to its exceptional performance, the P207 Pillow Block Bearing is known for its straightforward installation process. The bearing can be mounted and dismounted with ease, reducing downtime and eliminating unnecessary labor costs. Regular maintenance is also hassle-free, thanks to the bearing's accessible design, allowing for quick inspections and lubrication.Company Overview:The company behind the P207 Pillow Block Bearing is a leader in the manufacturing and distribution of high-quality mechanical parts and components. With a rich history spanning several decades, the company has built a reputation for excellence and innovation within the industry. Their commitment to research and development has enabled them to stay at the forefront of engineering advancements, ensuring that their products, including the P207 Pillow Block Bearing, remain at the pinnacle of quality and performance.Conclusion:The P207 Pillow Block Bearing represents a paradigm shift in the field of mechanical engineering. Its durability, versatility, and self-alignment capabilities set it apart from conventional bearings, making it an attractive choice for engineers, manufacturers, and maintenance professionals worldwide. As industries continue to evolve and demand higher standards, the P207 Pillow Block Bearing leads the way with its exceptional features, demonstrating a commitment to innovation and excellence in the engineering sector.

New Report Reveals Latest Findings in Tech Industry

In the latest news, [company name] has announced a groundbreaking partnership with [brand name] to revolutionize the [industry] industry. This collaboration is set to bring about a new era of innovation and advancements in [industry] technology. [Company name] is a leading [industry] company that specializes in developing cutting-edge technology solutions for [industry] applications. With a strong focus on research and development, [company name] has been at the forefront of pushing the boundaries of [industry] technology. Their commitment to excellence and innovation has made them a trusted partner for businesses across the globe.On the other hand, [brand name] is a renowned [industry] brand known for its high-quality products and commitment to sustainability. With a strong presence in the market, [brand name] has established itself as a leader in the [industry] industry, setting the standard for excellence and innovation.The partnership between [company name] and [brand name] is set to leverage the strengths of both companies to develop and commercialize groundbreaking [industry] solutions. By combining the expertise and resources of both companies, they aim to deliver products and services that will address the evolving needs of the [industry] industry.One of the key areas of focus for this partnership is the development of advanced [industry] technologies. With the rapid evolution of the [industry] industry, there is a growing demand for more efficient and sustainable solutions. Through this collaboration, [company name] and [brand name] aim to develop cutting-edge technologies that will set new benchmarks for performance and sustainability in the [industry] industry.Additionally, the partnership will also focus on enhancing the customer experience in the [industry] industry. By leveraging [brand name]'s expertise in customer engagement and [company name]'s technological capabilities, the companies aim to deliver a seamless and personalized experience for their customers, setting a new standard for excellence in the industry.Another important aspect of the partnership is the focus on sustainability. Both [company name] and [brand name] are committed to developing sustainable solutions that minimize the environmental impact of the [industry] industry. Through this partnership, they aim to develop and promote sustainable practices that will contribute to a greener and more sustainable future for the industry.The collaboration between [company name] and [brand name] is expected to have far-reaching implications for the [industry] industry. By bringing together their respective strengths and resources, the companies are poised to drive significant advancements in [industry] technology and set new standards for excellence in the industry.In conclusion, the partnership between [company name] and [brand name] marks a significant milestone in the [industry] industry. By combining their expertise and resources, the companies aim to deliver groundbreaking innovations and set new benchmarks for performance, sustainability, and customer experience in the industry. This collaboration is a testament to their commitment to driving positive change and shaping the future of the [industry] industry.